What's the cost of a corrosion resistant coating? Let's take a look at the real cost of buying and maintaining a corrosion resistant surface. Hint, buying on the cheap may be the most expensive option.

Corrosion is not simply a maintenance problem. Corrosion can have a multitude of adverse effects like poor product yield, product contamination, damage to costly instrumentation, and low productivity. To the extreme, corrosion can become a real drag on profitability. According to US Government studies, corrosion costs the US $276+ billion annually, that's why there's a huge market in corrosion control. But what's the true cost of implementing a corrosion solution?

|

In this blog you will learn:

- How Dursan and Silcolloy corrosion resistant coatings perform compared to stainless steel and super alloys

- Factors to consider when comparing corrosion resistant materials or coatings

- Get a relative cost of various corrosion resistant materials

- How life cycle costs can be a major factor in selecting a corrosion resistant material

|

First Consideration. Is The Corrosion Solution Effective?

Before we discuss the true cost of a particular corrosion solution it's a good idea to be sure the material or coating in question are chemical resistant and effective in preventing or limiting corrosion. Let's compare the effectiveness of corrosion resistant materials under various corrosive and temperature conditions.

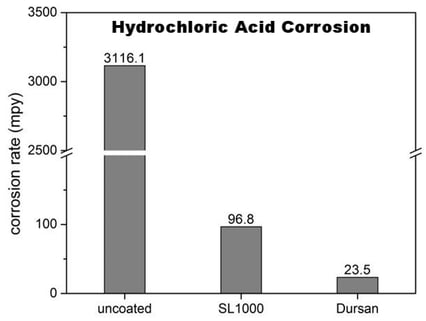

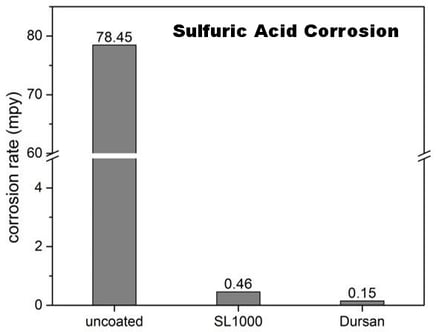

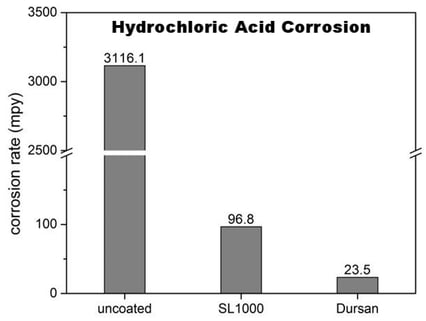

The ASTM G31 immersion test (below) compares an uncoated 316L coupon with Silcolloy® and Dursan® coated coupons. The coupons were immersed in a 20% HCl heated to 50 C. After 7 hours the coupons were extracted, cleaned and weighed. Corrosion rates where calculated based on weight loss. The baseline corrosion solution, stainless steel, had a very high corrosion rate. Use under similar conditions would require frequent maintenance and could potentially impact production if used in critical performance areas. The Silcolloy coupon had significantly less corrosion but would likely require regular maintenance. The Dursan coupon had about 1% of the corrosion rate compared to stainless steel, showing potential benefits to maintenance and operations cost.

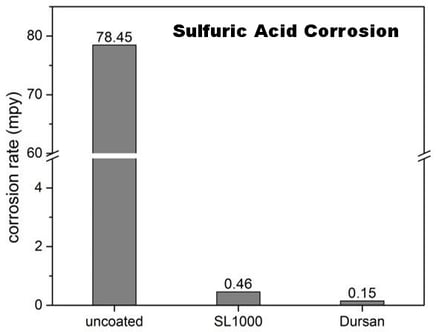

Comparative ASTM G31 immersion testing in a sulfuric acid solution shows similar performance with the Dursan coated coupon performing exceptionally in the application with orders of magnitude reduction in corrosion rate.

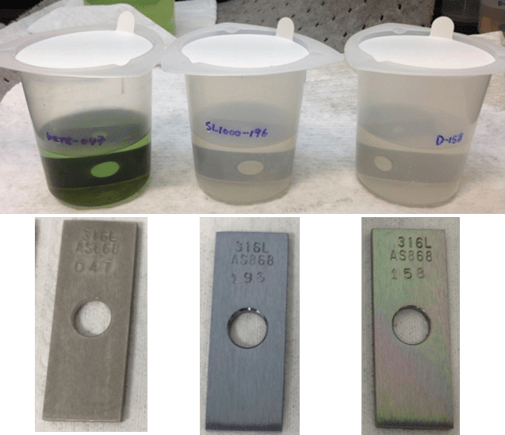

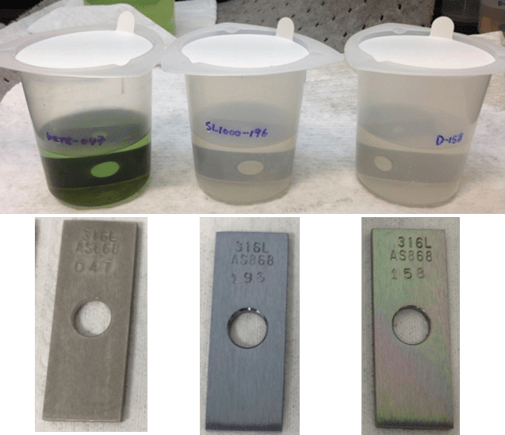

Here are images of the sulfuric acid test. The uncoated 316L coupon (left) is significantly damaged by the sulfuric acid. Additionally the acid solution is contaminated by the stainless steel, turning the fluid green. The coated coupons remain undamaged and the sulfuric acid solution is not contaminated. This could protect process fluids from contamination and improve yields.

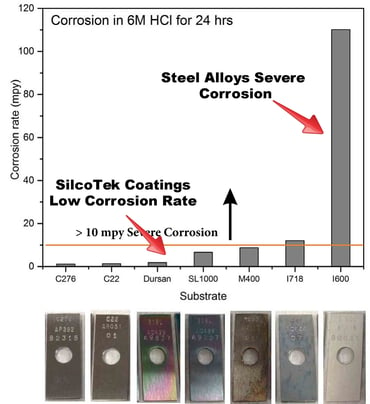

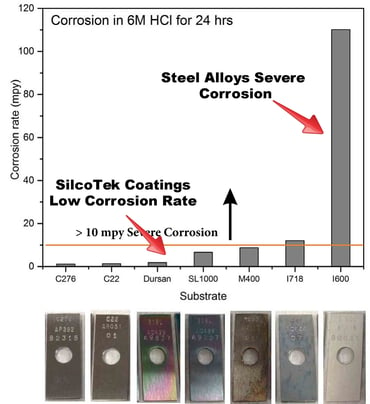

Let's throw some superalloys into the mix and see how they perform. In this comparison, we immersed coupons into 6M HCl for 24 hours and then measured the corrosion rate. The superalloys, C276 and C22, performed the best, followed by the Dursan and Silcolloy coated coupons.

We've compared the performance of various surfaces and found superalloys perform the best, followed by Dursan coated stainless steel, and finally stainless steel. So the most cost effective corrosion solution are superalloys, right? Well maybe yes and maybe no. It all depends on the application. Let's compare the cost of various corrosion resistant products.

How Much Vs. How Effective? The Cost Benefit of Corrosion Resistant CVD Coatings.

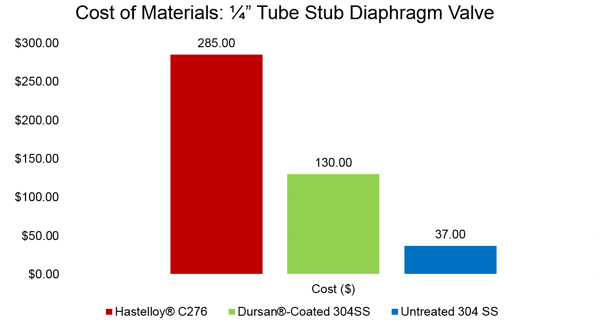

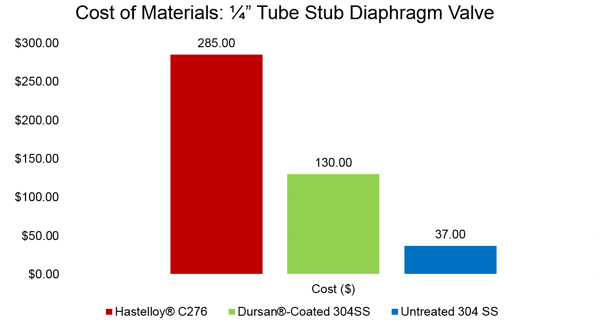

First let's compare the cost of a valve manufactured using a superalloy, Dursan coated, and stainless steel. The stainless steel valve is the cheapest, a fraction of the cost of Dursan or superalloy valve. But remember the poor corrosion resistance of the stainless steel? That poor performance could mean you'll be replacing that cheap valve 10 times during the useful life of the project or system. That means the stainless steel valve is actually the most expensive at $370.00. And that doesn't include the labor cost associated with replacing the valve and the lost productivity while the process or product is down. Depending on application, the Dursan coated stainless steel valve offers a good mix of improved corrosion performance and cost. For a 4x cost increase you get more than a 10X improvement in corrosion resistance. The superalloy valve costs about 8x more but does not significantly improve corrosion performance over the Dursan valve (based on ASTM G31 tests).

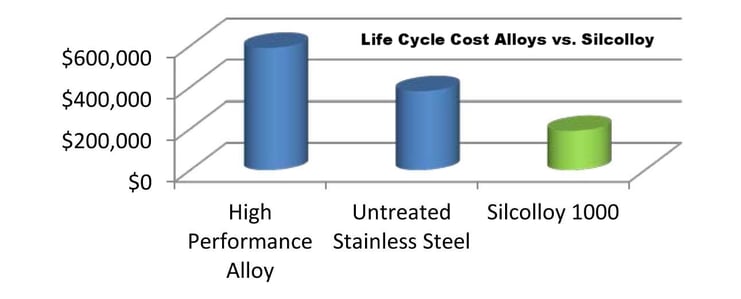

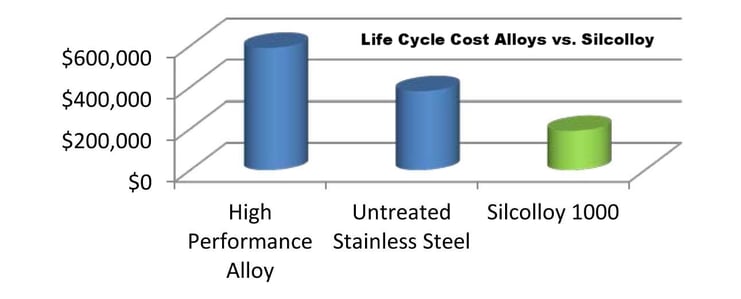

Comparing the life cycle cost of operating a typical stack sampling system shows that after factoring in capital cost and component replacement cost; Silcolloy or Dursan coated stainless steel surfaces are the clear cost leader when compared to high performance alloys and untreated stainless steel.

The Big Concern. Picking The Best Corrosion Resistant Material For The Application

Factors to consider when calculating the true cost of a particular corrosion solution include:

- The criticality of the application. If you can't afford downtime or a corrosion failure may cost you a bundle, the superalloy may be good insurance against failure.

- Length of service. How long will the part be in service? If the part is intended to be used for only a few weeks, a stainless steel component may perform just fine. For intermediate duration or long term use Dursan or a high performance alloy may be a more appropriate and cost effective solution.

- How sensitive is the process to contamination? If corrosion particulates or ion contamination endangers product quality or yield, it may be ideal to coat the flow path regardless of duration of use. For extreme sensitivity to metal ion contamination, coating a high performance alloy with Dursan or Silcolloy may be the most cost effective solution. Dursan and Silcolloy do not contain metals, making a completely metal free and corrosion resistant surface.

- Ease of replacement. How easy is the part to replace? Ease of access may factor in selecting a cost effective corrosion solution.

- Cost of part. If the part is an expensive instrument probe, it would be highly cost effective to coat the part with Dursan.

It's clear that material cost is not the only factor when selecting a cost effective corrosion solution. Weigh all factors carefully before committing to a corrosion resistant product. Want to learn more about improving the corrosion resistance of your product at the fraction of the cost of superalloys?