Stainless steel is pretty pure isn't it? Well that depends. In this blog we discuss potential contamination of sensitive analytical instrumentation.

Can Stainless Steel Outgassing Contaminate My Process?

Well that depends on the application and process requirements. Silcotek® coatings are used to enhance the surface and material properties of instrumentation throughout industry. But there's one coating property that has many applications for research and analytical applications, that's high purity. Specifically high purity silicon and how it can help to prevent process contamination in stainless steel flow paths.

|

In this blog post you will learn:

- How high purity silicon barrier coatings help to prevent process contamination from stainless steel outgassing.

- Learn about stainless steel outgassing when surfaces are exposed to heat and vacuum.

- How low surface energy coatings help to manage moisture contamination.

|

Silicon Coatings Act as a Barrier and Prevent Contamination

Silicon Coatings Act as a Barrier and Prevent Contamination

SilcoTek® barrier coatings dramatically reduce outgassing of stainless steel surfaces, improving pump down efficiency and virtually eliminating surface burn-in requirements. Coated vacuum and critical flow path surfaces improve process efficiency and productivity but they also prevent contaminants and moisture from migrating from the stainless steel surface and potentially impacting sensitive process fluids or analytical test instrumentation.

Want to learn more about inert surfaces and how they can improve the performance of your products or analytical test quality?

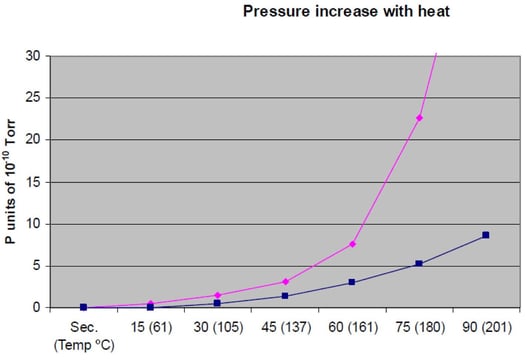

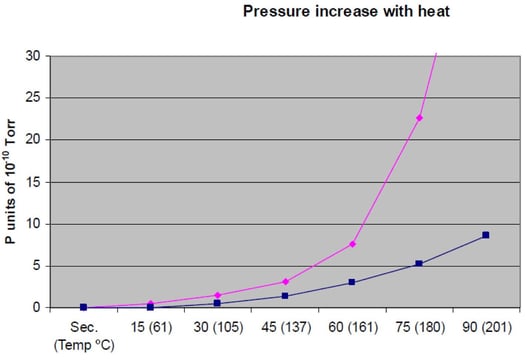

To show how contaminants can migrate from the stainless steel surface, we measured the base pressure of a stainless steel vacuum chamber (pink line below) and compared it to a silicon coated (SilcoNert coated) stainless steel chamber (blue line). The stainless steel chamber base pressure increased dramatically as the chamber was heated. The SilcoNert coated chamber base pressure increased but at about a 4x less rate. This shows that contamination from water, oils or other contaminants are significantly reduced.

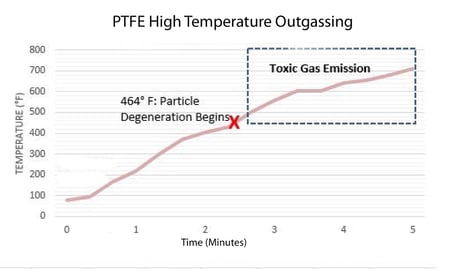

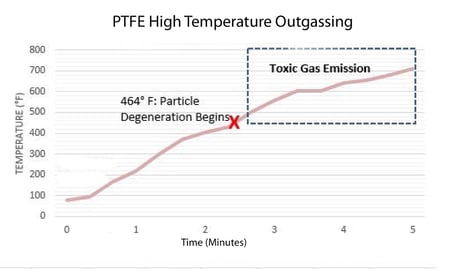

Other materials that are inert under ambient conditions can begin to outgas severely when heated. PTFE for example can begin to emit toxic contaminants at temperatures above 460°F as seen in the graph below.

Other materials that are inert under ambient conditions can begin to outgas severely when heated. PTFE for example can begin to emit toxic contaminants at temperatures above 460°F as seen in the graph below.

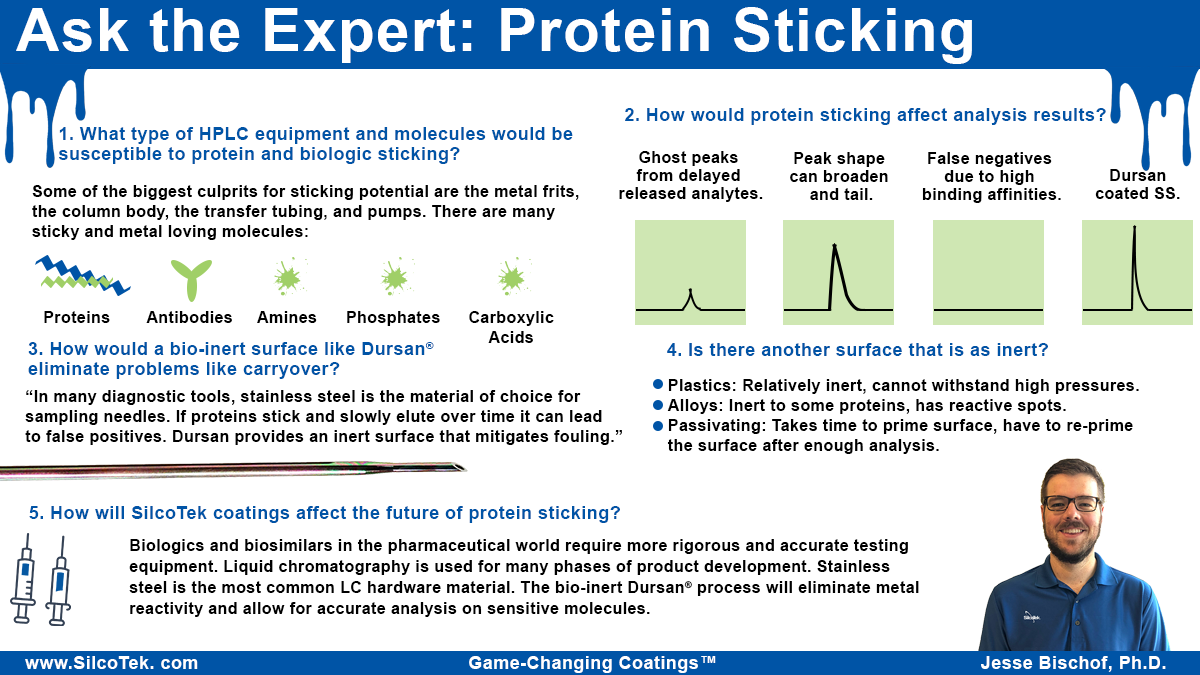

Stainless steel can be highly reactive even under ambient conditions. Potentially reactive chemicals can degrade stainless steel or bind to the stainless steel surface causing retention of potentially key compounds. Comparing the inertness of stainless steel vs. a SilcoNert coated surface shows improved response and inertness by orders of magnitude.

/Inertness%20Response.png?width=469&name=Inertness%20Response.png)

How Silicon Coatings Prevent Contamination

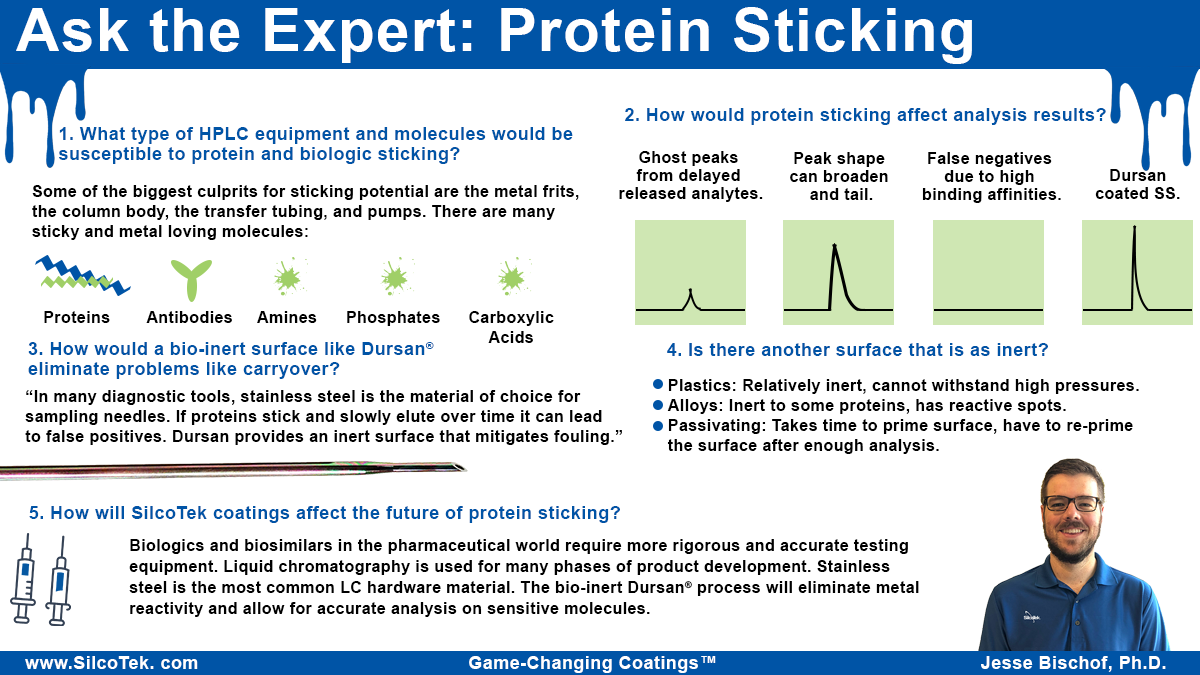

How do silicon coatings bond to stainless steel and prevent contamination? SilcoTek® high purity silicon coatings do not adsorb moisture or other system contaminants. That's because silicon coatings prevent organics and moisture from bonding to the surface. Even some types of proteins don't stick to silicon surfaces. Read the expert discussion below:

How are the Coatings Applied to Flow Path Surfaces?

Coatings like Dursan and SilcoNert bond securely to stainless steel surfaces (and even flexible bellows surfaces) so the entire flow path and seal areas are coated in a moisture repelling non-stick and non-reactive coating. The coatings are applied by a chemical vapor deposition process in which the stainless steel surface is heated in a high purity vacuum environment. The silicon coating is applied in a gas phase which bonds to the surface. Even fritted metal surfaces and precision high tolerance surface can be coated with minimal dimensional changes to the flow path.

Read our previous blog post about applying CVD coatings to stainless steel.

After application, the coating will flex with metal surfaces while remaining tough and durable, allowing leak free face seal and conflat sealing.

Benefits of a high purity coating in reactors:

-

-

- No contamination from metals

- Faster chamber pump down

- Easier chamber cleanup

- Improved process control

- Minimal burn-in

Interested in testing our coatings? Get free test coupons or contact our Technical Service Staff to arrange a coating trial.

Other Benefits of a Contaminant Free Surface

Product Testing

Product Testing

If sophisticated analytical tools like scanning electron microscopes are used for quality control, analysts can increase process throughput and prevent product adulteration during testing by coating chamber and critical flow path surfaces with a contaminant free non reactive surface. As shown above, moisture and other contaminants don't stick to SilcoTek® coatings, improving SEM pumpdown and preventing product contamination.

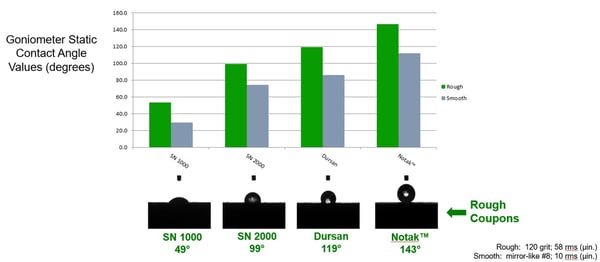

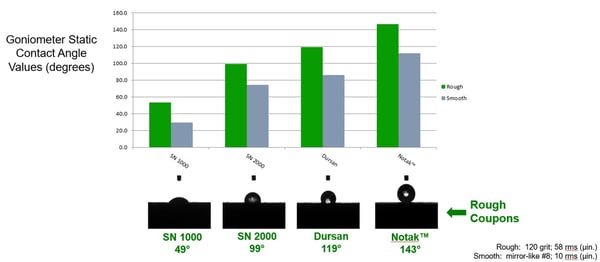

The moisture repelling comparison below highlights the hydrophobic characteristics of various silicon surfaces. Our most hydrophobic surface, Notak, is a polymer based material that is bonded to the surface.

How do Dursan® and Notak™ improve moisture resistance? They feature a low surface energy high contact angle surface that is bonded to all wetted surfaces by chemical vapor deposition. Moisture contact angles of over 140° can be achieved. That means water and other contaminants won't bond to flow path surfaces, preventing product contamination .

Product Testing Benefits

- Rapid contaminant free testing

- Higher productivity

- Fewer test failures

Are There Byproducts From SilcoTek Coatings? What are these coatings made of?

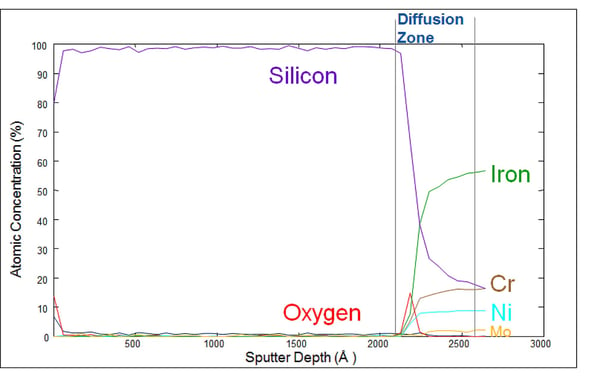

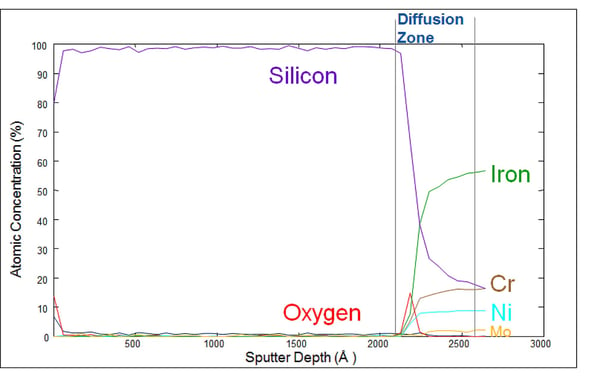

Most of our coatings are made of silicon. We functionalize (or "dope") the surface for specific inertness performance but our Silcolloy coating and SilcoNert 1000 coatings are made of silicon with a native oxide surface. Non reactive silicon makes an excellent barrier which prevents contamination from the base metal, glass, or ceramic surface. The Auger Electron Spectroscopy (AES) diagram below of a SilcoNert surface shows the coating contains silicon and oxygen. Note the diffusion zone where the silicon is bonded to the stainless steel base.

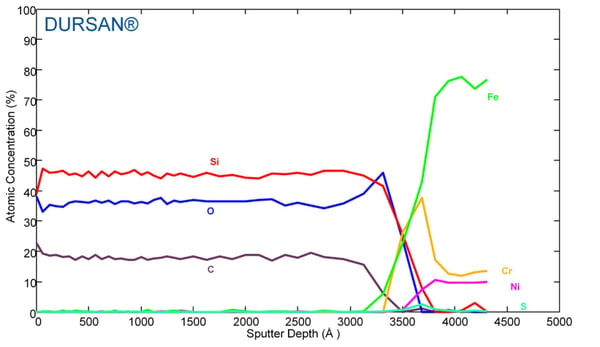

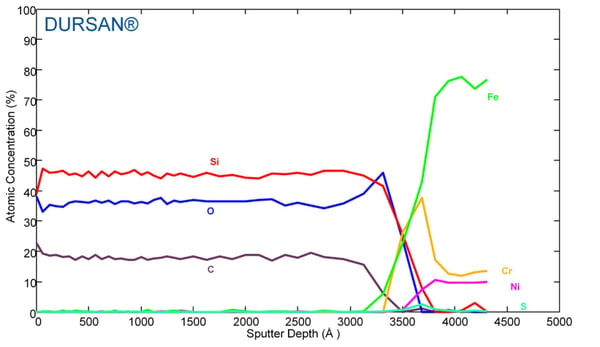

Dursan® is a different coating consisting of silicon, oxygen and carbon. The Auger plot below shows the coating depth and a similar diffusion zone to SilcoNert.

Want to learn more about how our coatings improve the performance of your products?

Or ask our experts on LinkedIn.

Other materials that are inert under ambient conditions can begin to outgas severely when heated. PTFE for example can begin to emit toxic contaminants at temperatures above 460°F as seen in the graph below.

Other materials that are inert under ambient conditions can begin to outgas severely when heated. PTFE for example can begin to emit toxic contaminants at temperatures above 460°F as seen in the graph below.

/Inertness%20Response.png?width=469&name=Inertness%20Response.png)