We discuss how high nickel prices may be a problem for nickel alloys and corrosion resistance applications. Learn how coatings can help relieve the pain.

We discuss how high nickel prices may be a problem for nickel alloys and corrosion resistance applications. Learn how coatings can help relieve the pain.

How the Nickel Market May be a Problem for Corrosion Resistance

Early in 2022 nickel was a sleeping commodity traded routinely around the world. Prices were stable and all was well on the leading metals exchange, the London Metals Exchange or LME. Then February happened.

In this blog we'll discuss how high nickel prices may effect super alloy supply and prices and how silicon coatings offer a low cost solution.

|

In this blog post you will learn:

|

Background and Nickel Prices

During normal times any commodity producer will buy short contracts (a bet that the future price of their product will drop) on the LME. They do this not because they want the price of their product to drop, they're actually buying insurance in case the price does drop. That way their losses are reduced (hedged) against the profit from the short futures contract. That's what Tsingshan Holding Group, and many other metals companies did. Tsingshan is a Chinese steel conglomerate who happens to own lots of nickel mines. If you look at historical nickel price swings* (see the graph below), there appeared to be little risk of a huge run-up of Nickel prices. A big price bump (or a short squeeze) would mean Tsingshan would be responsible for filling those nickel contracts at a loss.

Then on February 24th, Russia invaded Ukraine and all bets were off. That's because Russia supplies about 7% of the world nickel. As the war raged on, the West imposed trade restrictions and sanctions on Russia, essentially cutting off much of that nickel from Western mills and roiling markets. On March 4th (a Friday) the price for a ton of nickel had increased from about $20,000 per ton to $29,000 per ton on the LME. By the following Tuesday nickel was trading at over $100,000 per ton! The loss of supply and speculation raised havoc in the market and caused the LME to shut down nickel trading for a week. There was fear that margin calls could be missed and nickel mines that held short contracts would be facing billions in losses.

Since that faithful March 8th day, the LME price for nickel has stabilized somewhat but trading continues to be volatile. Nickel prices dropped to $48,000 per ton on March 8th after that huge spike and have further eased to a still lofty $31,000 per ton as of Monday March 21st . But the market volatility will certainly drive up the price of metal alloys containing nickel, especially high nickel alloys, like Hastelloy® C22 or C276 in the future.

Why will nickel super alloys see a big price increase? Let's look at the nickel concentration in various commonly used alloys. 316 stainless steel is composed of 10 – 14% nickel, 304 stainless steel has a composition of about 8% nickel. Conversely, Hastelloy C276 contains over 60% nickel and C22 contains about 56% nickel. You can see that a spike in nickel prices will disproportionally impact the price of the high nickel alloys. Compounding the problem, the War in Ukraine and consequential sanctions have reduced the supply of nickel. The overall effect being high prices and potential shortages or long lead times for high nickel alloys.

Silicon Coatings as a Stop Gap in Corrosion Applications

To fill the supply gap for corrosion resistance applications Dursan® or Silcolloy® coated stainless steel may be an option. The benefits of using corrosion resistant coatings include:

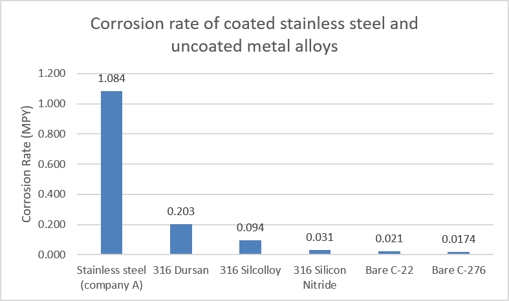

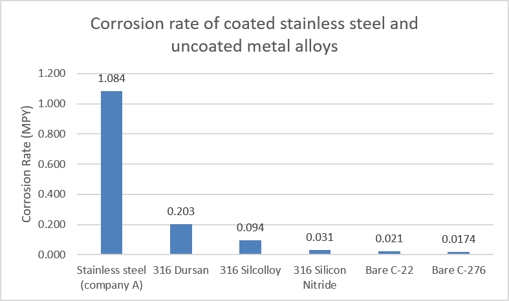

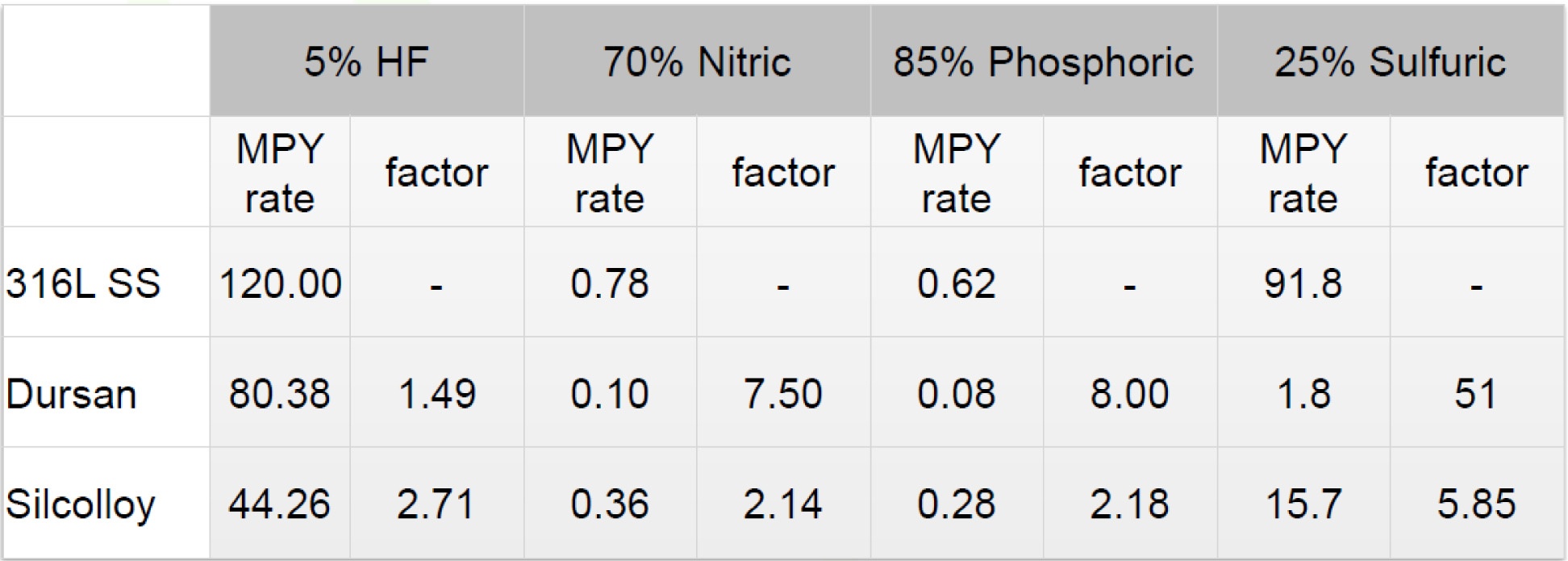

Comparable Corrosion Resistance, Comparing the Corrosion Resistance of 316 Stainless Steel

Dursan® and Silcolloy® coated stainless steel improve the corrosion resistance of stainless steel by an order of magnitude, approaching the performance of Hastelloy® C-22 and C-276. The graph below compares the corrosion rate of stainless steel, Dursan and Silcolloy coated stainless steel, silicon nitride coated stainless steel, and super alloys after being subjected to identical corrosive environments. The Dursan and Silcolloy coated stainless steel coupons vastly improved the performance of stainless steel, approaching the performance of the super alloys. SilcoTek offers new custom coatings that further improve that performance. We'll be discussing those improvements in future blogs. For now, contact our Technical Service Team to learn more.

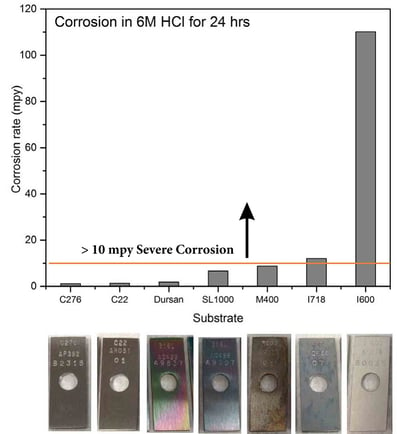

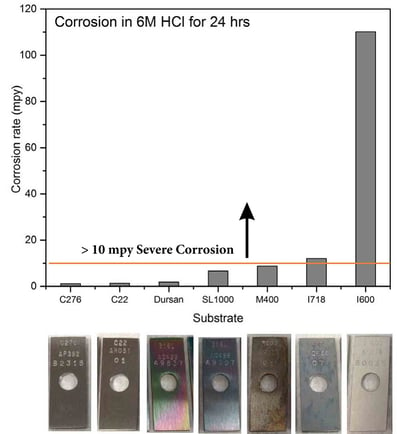

Dursan and Silcolloy (SL1000) coated stainless steel hydrochloric acid (HCl) immersion testing (below) shows comparable to improved performance over various nickel alloys, including C22, C276 and M400 alloys.

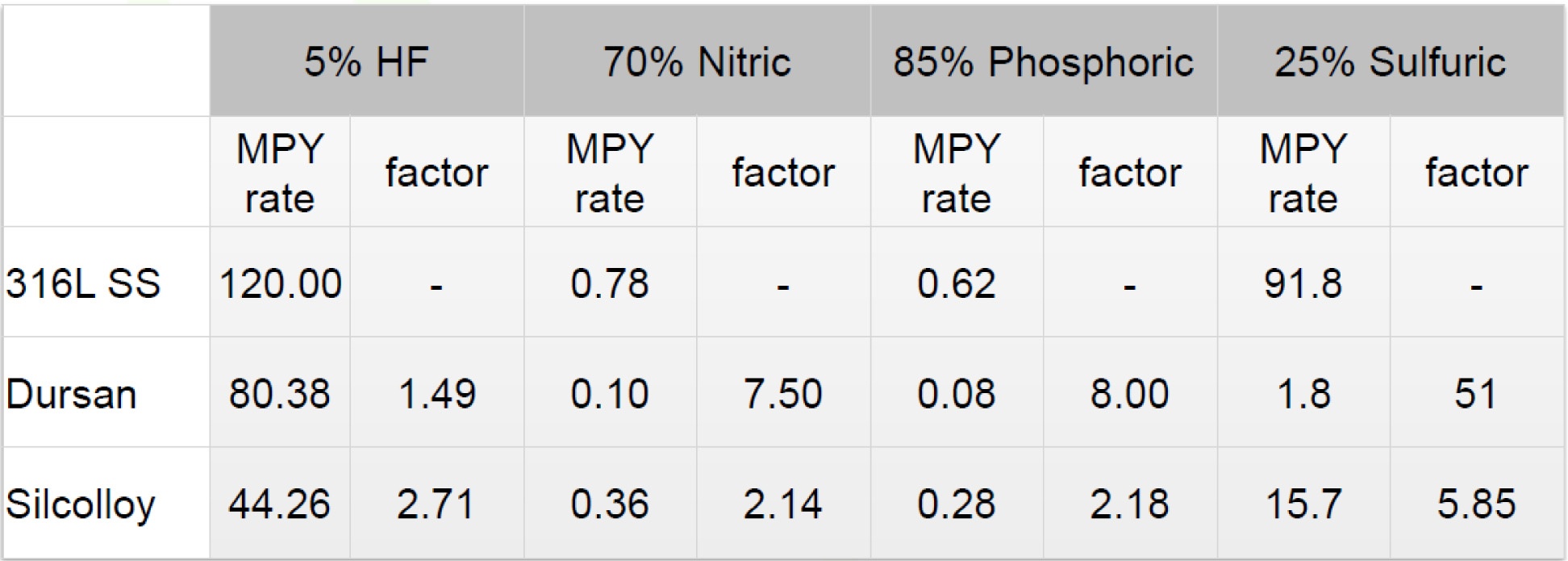

Dursan and Silcolloy improve the corrosion resistance of stainless steel for various applications, including those listed in the table below.

Improve the Performance of Super Alloys

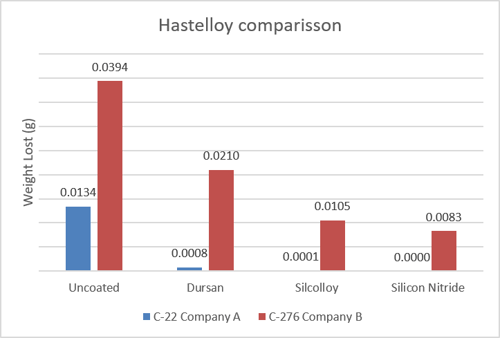

As an alternative cost saving measure for applications that require the use of a high nickel alloy, users should consider extending the life of the super alloy component by applying corrosion resistant coatings to the alloy surface. After investing in a super alloy, it makes sense to protect the investment by adding a layer of silicon to further improve corrosion resistance and increase the life of that component.

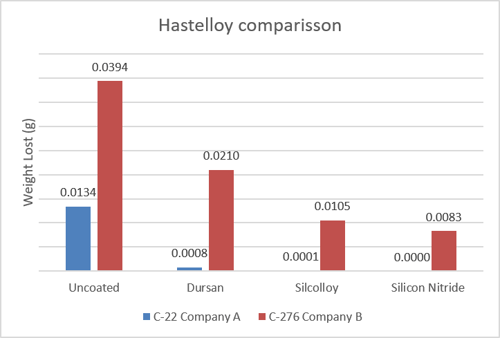

Applying Dursan or Silcolloy to super alloy components can further improve the performance in corrosive applications. The comparison below shows how coating a Hastelloy coated sintered metal disc can reduce loss due to corrosion when immersed in HCl solution.

Sintered Disc Protection

Reduce Cost

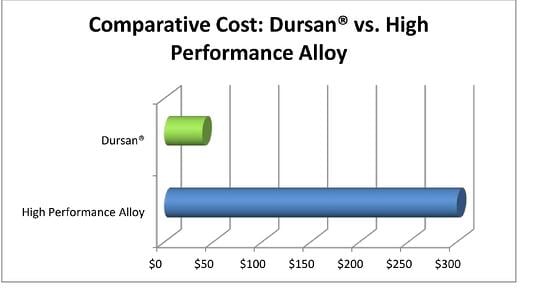

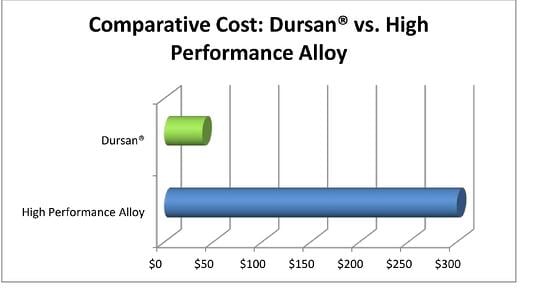

Even prior to the run up in nickel prices, super alloy prices were high. Often the cost of a coated stainless steel part can be a fraction of the comparable component made from a super alloy. The comparison below, evaluated prior to the run up in nickel prices, shows that Dursan coated stainless steel can significantly reduce the cost of a product.

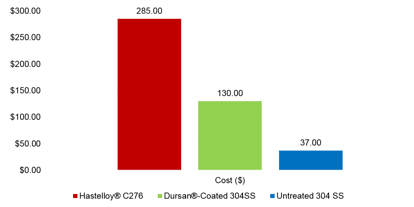

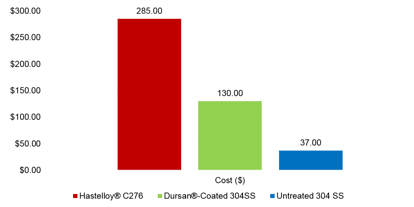

The cost comparison below demonstrates how silicon coated stainless steel can be an effective solution to high super alloy prices. The price of a tube stub diaphragm valve (graph below) shows that a Dursan coated 304 stainless steel valve is about half the price of the super alloy valve.

Availability is also a concern. If the application requires the use of a super alloy, the lead time can be so long that the project may be in jeopardy. The lead time for most SilcoTek coatings in standard part configurations is 10 working days or less, making silicon coatings a safe bet for meeting your project deadline.

Summary

The world is experiencing extraordinary volatility in the price and supply of key materials used in manufacturing metal alloys, nickel is a prime example. The market stress caused by tariffs, COVID, and now sanctions on Russia have resulted in a storm of price and delivery uncertainty.

SilcoTek® coatings significantly improve the corrosion resistance of stainless steel which helps relieve the need for high nickel alloys in many applications. Coatings can also be used as a stop gap to keep a project on track by avoiding long lead times or they can be used to protect a significant investment in super alloy components. As an alternative to super alloys, SilcoTek coatings are hard to beat.

To learn more about how SilcoTek coatings can improve the performance of your products, contact our Technical Service Team to discuss your application. To keep up with the latest in high performance coatings, subscribe to our blog, or follow us on LinkedIn.

Additional Reading About Nickel Prices

https://www.marketplace.org/2022/03/21/the-nickel-market-has-gone-bonkers/

https://seekingalpha.com/article/4495545-nickel-short-squeeze

*Image credit: Seeking Alpha

**Hastelloy® is a trademark of the Haynes® Corporation

Note: we're not financial advisors nor do we offer financial advice of any kind.

We discuss how high nickel prices may be a problem for nickel alloys and corrosion resistance applications. Learn how coatings can help relieve the pain.

We discuss how high nickel prices may be a problem for nickel alloys and corrosion resistance applications. Learn how coatings can help relieve the pain.