We say all the time that SilcoTek® coatings are used in a wide range of applications. But where exactly? Let's discuss specific methods and standards where our coatings are used.

SilcoTek® coatings are indeed used in a wide variety of applications. Coating uses range from mold release, process sampling, semiconductor manufacturing, oil and gas production, hydrocarbon processing, analytical testing and much more. But isn't that a pretty nebulous claim? How are the coatings used in test methods and do SilcoTek coatings comply with my industry standards? That's a valid question, so we rolled up our sleeves and pulled together some methods or applications that use our coatings. To be sure, there are many more applications and uses for our coatings, here are just a few on our list.

|

In this blog post you will learn:

- How SilcoTek® coatings are used in various industry standards and methods

- Benefits of using inert, corrosion resistant coatings in process flow paths

- How to improve the performance of flow paths used in specific applications or methods

|

OK, first a bit of a disclaimer. The methods we're listing may not specifically call out our coatings, some methods specify a performance criteria that can only be achieved by using inert coatings, other times products featuring our coatings or equivalent are called out. Want to learn about our coatings and applications? Get our free e-Book.

We searched methods and related products used in the method application to find industry approved or customer approved use of our coatings. For some applications we’re formally approved, in other uses we're referenced in tests or standards. Some applications call out a specific coated component either by our brand name or the customer brand. So we're casting a wide net to list as many standards and methods for various industries. Of course individual customers have their own approval process and methods which are not discussed. We don't list customer approved uses as they are confidential (we're not blabber mouths you know..). Anyway, enough of the disclaimers. Here are just some of the applications and benefits for some of the industries in which our coatings are used.

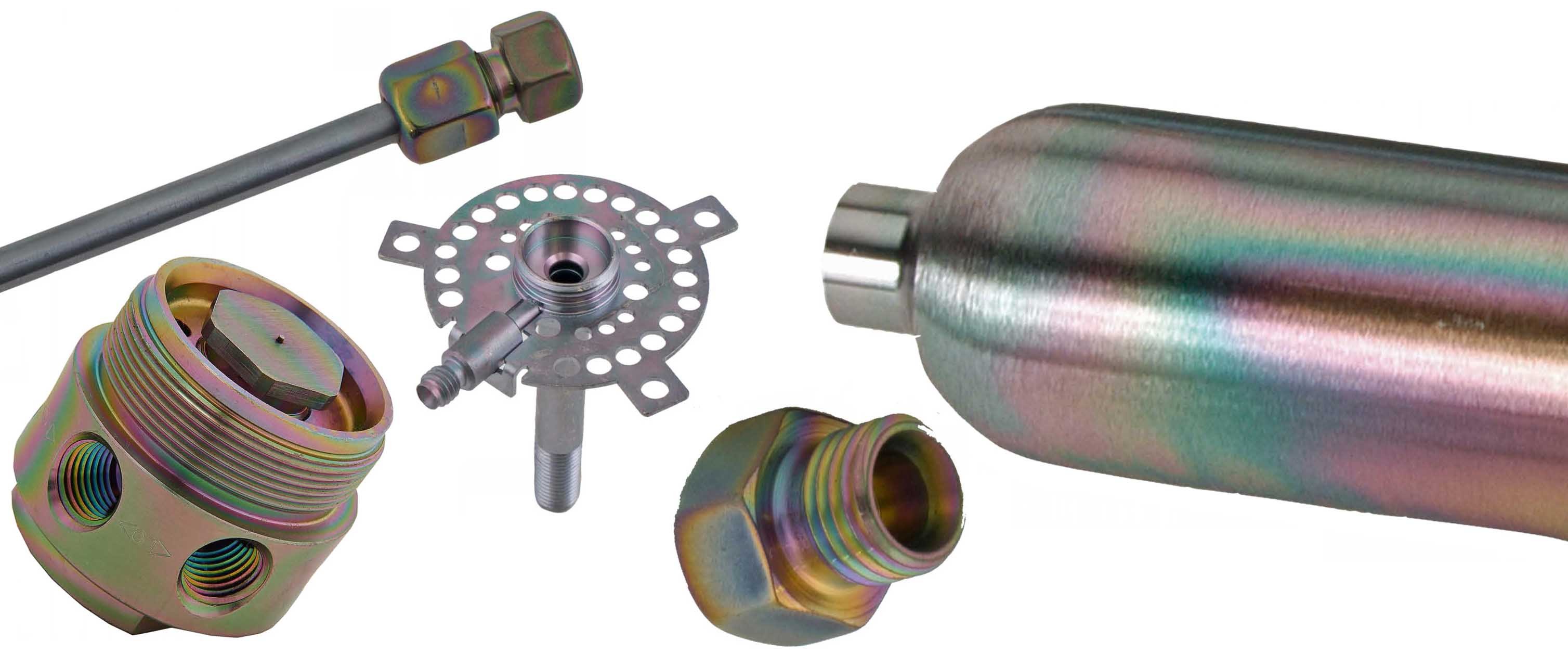

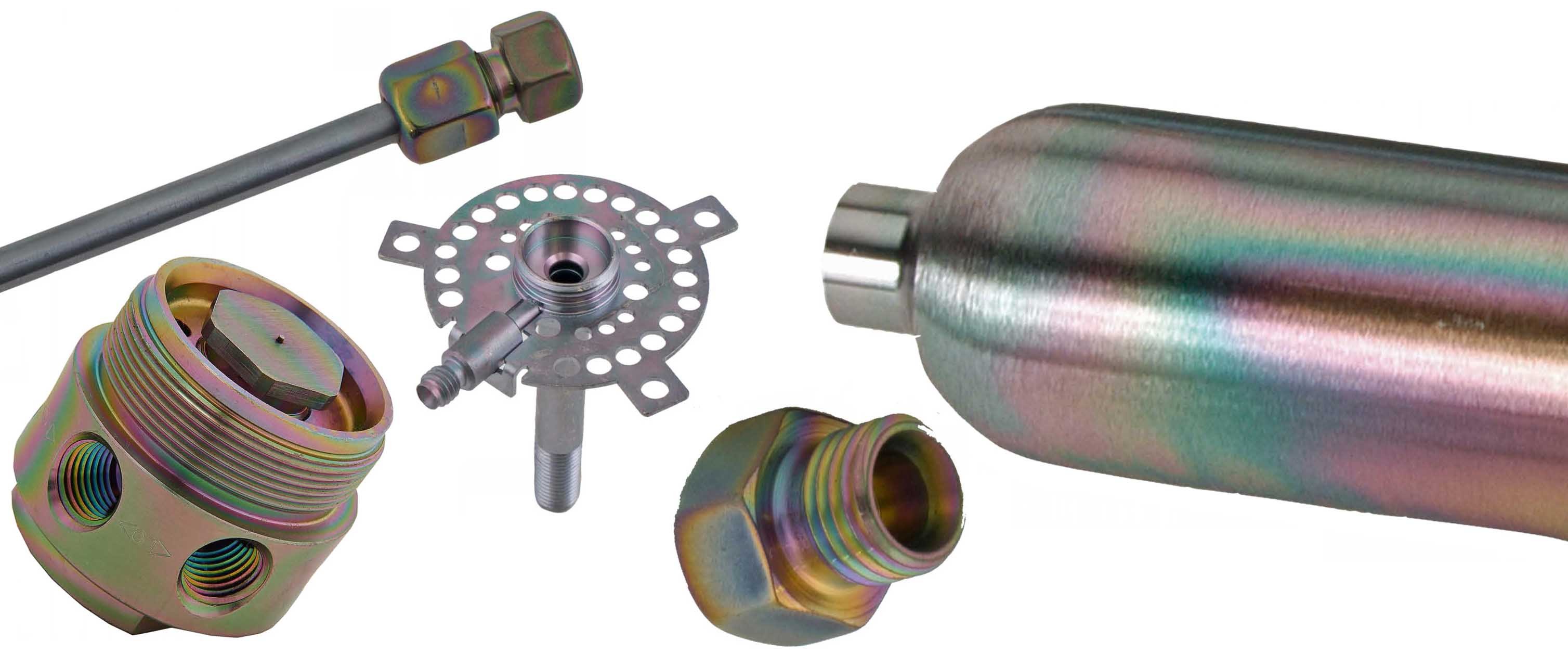

Refinery & Petrochemical / Spec Gas / Natural Gas / Oil & Gas Exploration

Related standards:

Benefits of using inert silicon coatings in hydrocarbon processing applications

- Faster response

- Accurate and reliable sulfur test results

- Faster calibration

- Fewer test failures

Get all the benefits of using SilcoTek coatings for hydrocarbon processing in upstream and downstream applications.

What about NACE standard MRO 175 (Materials for use in H2S containing environments)? Do SilcoTek coatings comply with this standard? No. MRO 175 specifies the base metals that are approved for H2S environments, not coatings. No coating will apply to MRO 175, only base metals. Our coatings when applied to MRO 175 approved metals will improve the surface inertness and improve H2S detection. The base metal will continue to comply with MRO 175. Applying our coatings to non compliant materials will not make them compliant, only inert to reactivity.

Medical and Pharmaceutical

Related Standards

Benefits to Medical and Pharma Testing

- Prevent chemical adsorption

- Reduce analyte carryover and contamination

- Prevent protein binding and sticking

- Improved flow path corrosion resistance

Get more information on use and benefits of bioinert coatings in medical diagnostic applications.

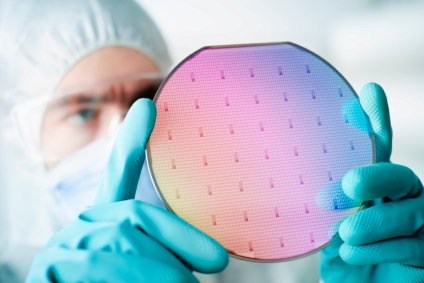

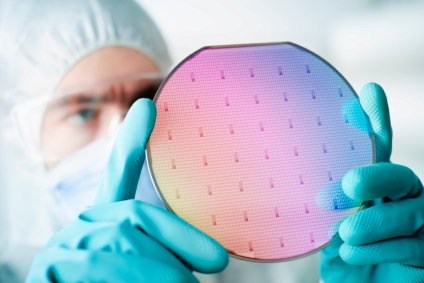

Semiconductor manufacturing

Related Standards

Several component applications apply for purity and corrosion resistance. Other applications include:

Benefits to semiconductor manufacturing

- Improved yields by reducing metal ion contamination

- More accurate trace environmental contaminant testing

- Improved equipment durability and corrosion resistance

Get more information on silicon coating benefits in semiconductor manufacturing.

Air Quality

Related Standards

Benefits to air quality testing

- Consistent trace level test results, ppb and ppt test capability.

- Improved peak resolution

- Improved sample stability during storage

Learn more about key factors in producing reliable VOC analysis.

Environmental Testing

Related Standards

Benefits to environmental testing

- Improved sample stability during sample collection and transfer

- Higher test peak resolution

- Improved low level detection

- High durability surface ideal for field testing

Go to our Analytical Solutions page to learn more about the benefits of our coatings in environmental testing.

About Corrosion Resistance

Our coatings are also tested to various corrosion standards. In this case our coatings are not part of the test method, we're the focus of the testing. Since corrosion testing applies to many industries, we thought it would be beneficial to list some of the methods used to evaluate our coatings for corrosion resistance. Our coatings have been successfully tested for corrosion resistance using the following standards:

Corrosion resistance benefits

- Extend the life of existing components

- Improve corrosion performance using existing materials and design

- High tolerance coating does not alter part fit or geometry

Get our corrosion test results.