Let's discuss some new applications and uses for our coatings. Some are really out there!

New Applications and Uses for Our Coatings

A wide range of industries have recognized the benefits CVD coatings offer. In this blog post we'll review some interesting new applications for inertness and corrosion resistance in various industries.

|

In this blog post you will learn:

- How diverse industries use our coatings while getting the most out of your analytical or process system.

- Learn about applications that may benefit your industry.

- Get information about CVD coating use in biomedical, HPLC, analytical, semiconductor, industrial, air monitoring, VOC analysis, and filtration.

|

Let's go through a few examples of some of the latest applications. Have a question about our coatings? Go to our Frequently Asked Questions page.

Breath Analysis

In April of 2022, the FDA authorized the first COVID-19 diagnostic test using breath analysis. A video on how this device works can be found here. The device is a small gas chromatography-mass spectrometry (GC-MS) unit that analyzes five specific VOCs. According to the FDA and Inspect-IR documents, the five VOCs are of the ketone and aldehyde families. Through the FDA trial process, it was found that the product has a 91.2% sensitivity (number of COVID positive individuals show a positive result on the product) and 99.3% specificity (number of individuals without COVID that show negative results on the product).

The pending patent from Inspect-IR shows that the instrument (originally designed to detect cannabis use) operates by concentrating the VOCs from an individual’s breath in a carbon based sorbent such as a carbon molecular sieve or a Carboxen® coated mesh. The sorbent is then heated to release the VOCs to a GC-MS system. While it does not specifically describe any SilcoTek® coatings in the system, the ultra-inert SilcoNert® 2000 would likely have beneficial impact to the system in allowing trace levels of VOCs of importance to make it from the breath to the mass spec without non-specific adsorption to metal components.

Learn how SilcoTek® coatings can improve your analytical system performance.

VOC Analysis for Fenceline, Process Monitoring, and Indoor Air Quality

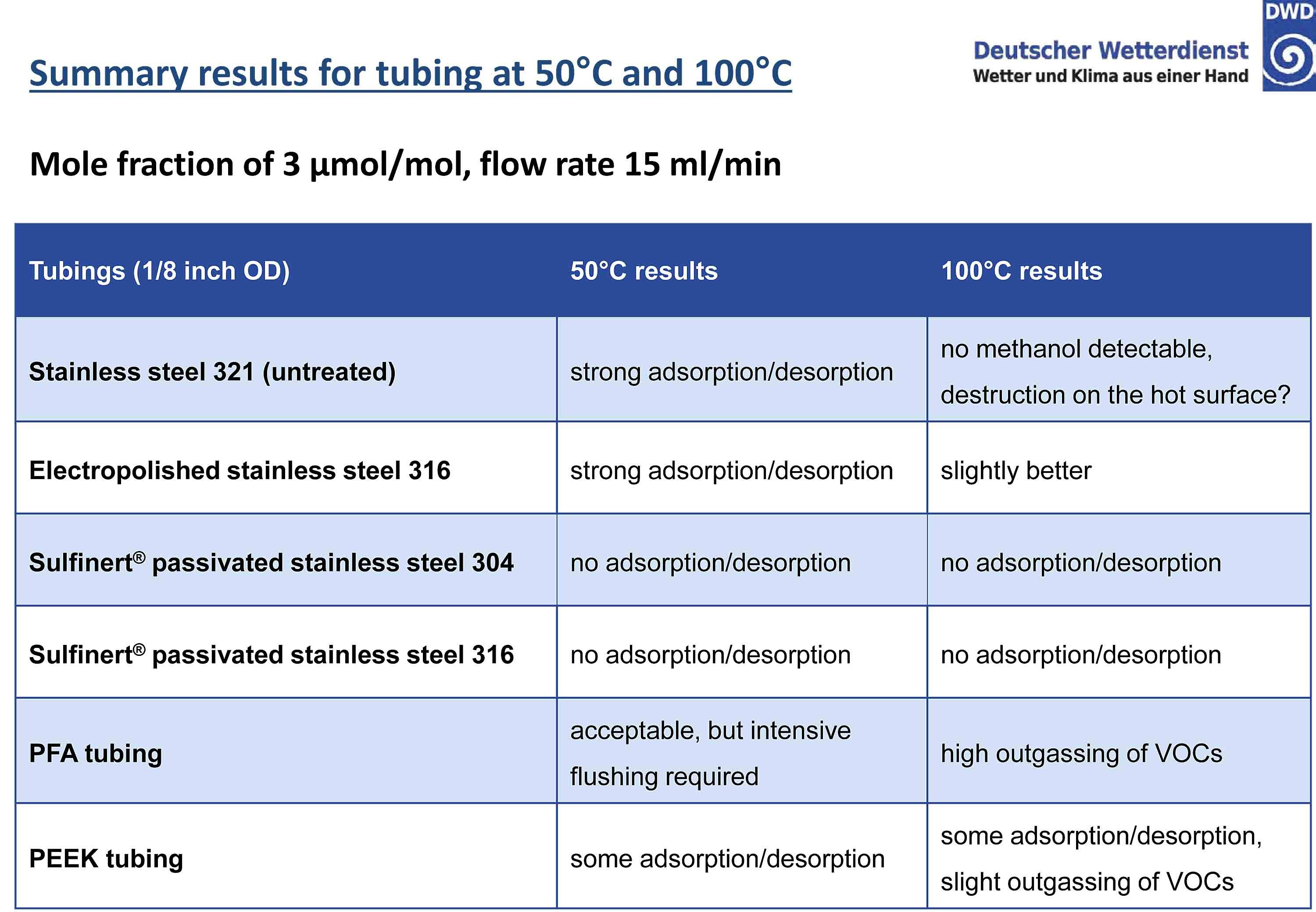

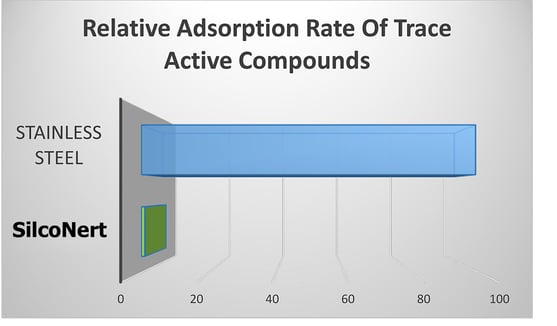

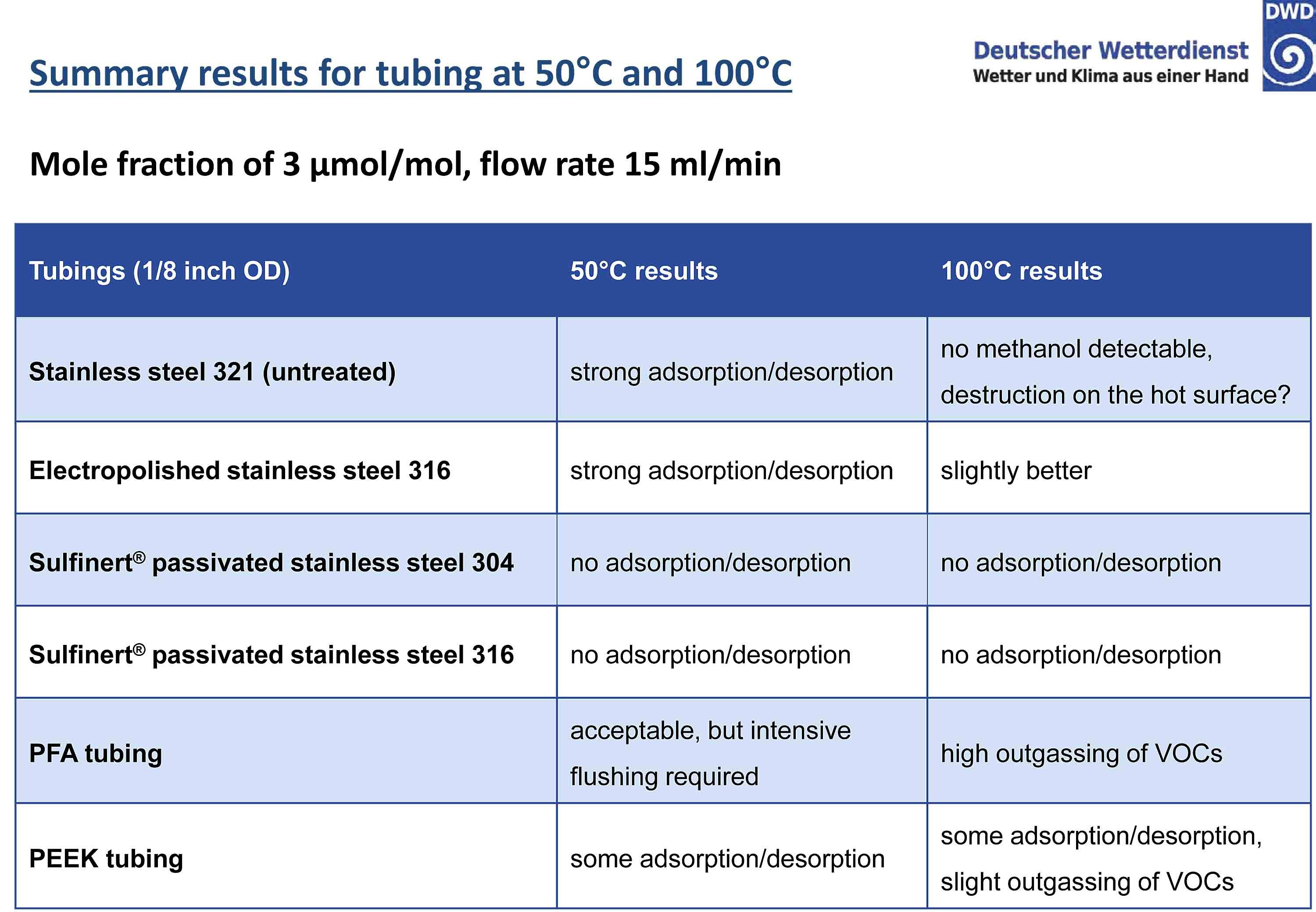

Many diagnostic tests occupy both laboratory time as well as technician time to produce/collect the sample. Some tests are better suited for real-time and non-invasive analysis. The real-time collection of VOCs (volatile organic compounds) which are directly transported to a mass spec is an attractive option. Recent scientific publications have focused on this concept and reported their results. In each case, the transfer pathway to the instrument (typically a mass spec) was coated by SilcoTek® to ensure the VOCs would be uninhibited in the flow path to the detector. Quantification of VOC adsorption was studied by the DWD (the Dutch Metrology Institute).

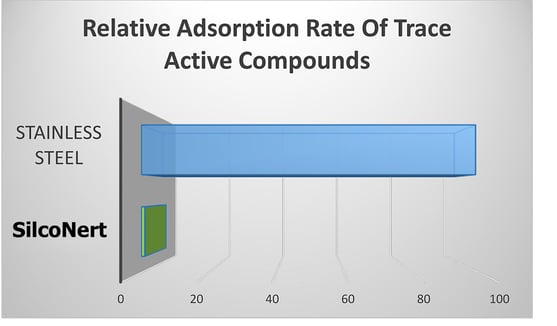

Comparative testing by the Dutch Metrology Institute (summary below) shows that SilcoNert® coated flow paths prevent adsorption and improve detection of VOCs.

First, a publication in the Journal of Breath Research developed a system to monitor dairy cattle located in a waiting area prior to milking. Depending on the VOCs that were analyzed, the researchers were able to identify headcount, the presence of paratuberculosis (a chronic intestinal infection), cows that had just recently given birth, as well as make predictions about quantities of milk that would be produced in that round of milking. A more recent study, which has open access permissions, took a similar approach, but monitored individuals rather than entire crowds. Their work focused on the separation of the cow breath VOCs and background VOCs (a common issue upon reading these types of articles), but they plan to further their work in using it to identify respiratory and metabolic illnesses before they become an issue for the entire herd.

First, a publication in the Journal of Breath Research developed a system to monitor dairy cattle located in a waiting area prior to milking. Depending on the VOCs that were analyzed, the researchers were able to identify headcount, the presence of paratuberculosis (a chronic intestinal infection), cows that had just recently given birth, as well as make predictions about quantities of milk that would be produced in that round of milking. A more recent study, which has open access permissions, took a similar approach, but monitored individuals rather than entire crowds. Their work focused on the separation of the cow breath VOCs and background VOCs (a common issue upon reading these types of articles), but they plan to further their work in using it to identify respiratory and metabolic illnesses before they become an issue for the entire herd.

Another use for Real-time VOC analysis is in exercise analysis. A publication from 2021 attempted to utilize VOC analysis from exhaled breath to potentially replace blood testing to analyze shifts in metabolites in the body. During exercise, these VOC and metabolite shifts are largely due to a change in fatty acid oxidation, glycolysis, and the Krebs cycle. There are several unknowns regarding the efficiencies of exercise plans, the individual genetic makeup of a person that may lead to non-optimal exercise (or potentially harmful exercise for an individual), as well as how one’s diet may impact exercise efficiencies. This publication was successful in analyzing VOCs from exhaled breath and matching them quite well with what is typically done via blood draws from athletes after moderate exercise. The advantage of real-time and non-invasive analysis techniques may lead to useful analysis in monitoring disease, medication response, and changes in metabolic and physiological functions.

Another use for Real-time VOC analysis is in exercise analysis. A publication from 2021 attempted to utilize VOC analysis from exhaled breath to potentially replace blood testing to analyze shifts in metabolites in the body. During exercise, these VOC and metabolite shifts are largely due to a change in fatty acid oxidation, glycolysis, and the Krebs cycle. There are several unknowns regarding the efficiencies of exercise plans, the individual genetic makeup of a person that may lead to non-optimal exercise (or potentially harmful exercise for an individual), as well as how one’s diet may impact exercise efficiencies. This publication was successful in analyzing VOCs from exhaled breath and matching them quite well with what is typically done via blood draws from athletes after moderate exercise. The advantage of real-time and non-invasive analysis techniques may lead to useful analysis in monitoring disease, medication response, and changes in metabolic and physiological functions.

Finally, a recent paper in Nature shows that changes in the composition of VOCs from exhaled breath can change when watching various types of videos. Upon watching these videos, the body and mind turn on and off various metabolic and physiological mechanisms and the team was interested in measuring those pathways via the participant’s breath. The study found that the video type had little impact on acetone, methanol and octenol. These three are typically byproducts of digestive pathways, and since the participants were not consuming any drinks or beverages during the test, these VOCs steadily increased or decreased regardless of the visual stimulus.

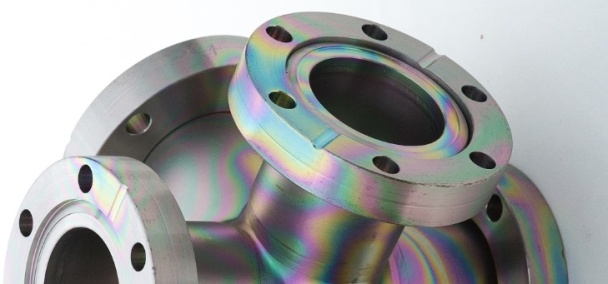

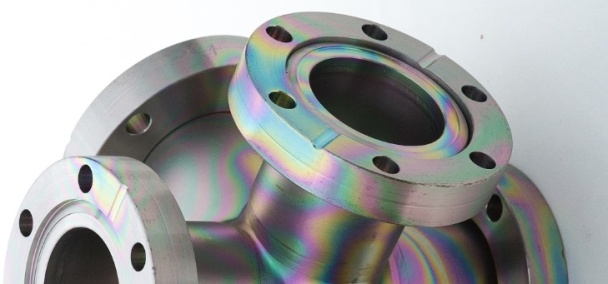

Filtration corrosion resistance

Metal filter corrosion and fouling can increase maintenance, reduce efficiency and contaminate product flow paths. Additionally metal fritted filters commonly used in analytical and lab applications adsorb reactive flow path samples, causing test failures and inconsistent test results. SilcoTek® high temperature CVD coatings, like Dursan® and SilcoNert®, prevent the interaction of process fluids and test analytes with the metal filter surface, reducing fouling, corrosion, contamination, and sample adsorption.

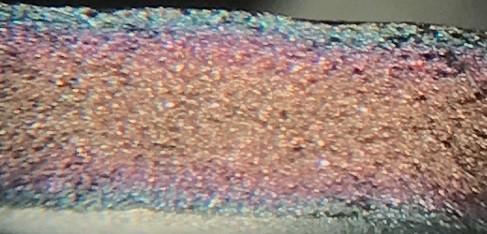

Additionally, our coatings won't plug filter media because our precision CVD deposition process distributes the coating without blinding of the filter surface or significantly impacting filter efficiency. A cross section of a precision coated filter (below) shows coating throughout the filter without blocking the pores.

Want to learn more about how we coat metal filters and sintered metal frits?

Read our Technical Insight.

The benefits of an inert, corrosion resistant and fouling resistant coating in filtration applications.

- Increase filter life, reduce maintenance

- Reduce product contamination

- Improve corrosion resistance and durability

- Improve process efficiency

- Consistent analytical results

- Won't block or obstruct the filter

- Minimize differential pressure

Surface Energy Modification for Hydrophobicity

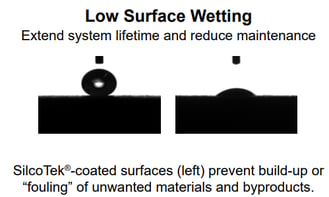

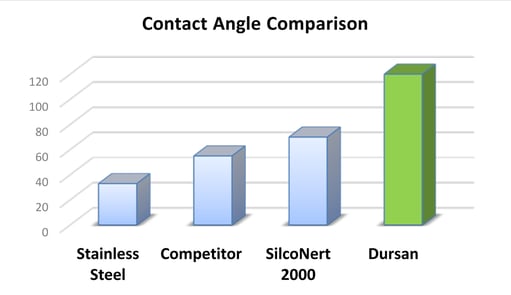

SilcoTek's patented silicon chemical vapor deposition (CVD) coating technology can be applied to complex or narrow part configurations without impacting even extremely tight tolerances. Comparative studies show SilcoTek non-wetting coatings, like Dursan, dramatically improve water repelling properties when applied to stainless steel, metal alloy, glass, or ceramic surfaces.

Solve common moisture related problems:

- Sample loss due to adsorption

|

|

Our low surface energy (high contact angle) surface repels water, preventing system contamination and improving analytical test reliability. Comparative testing shows the Dursan® coated surfaces significantly improve hydrophobicity by reducing surface energy by 60% or more. Surface energy water droplet testing below compares various coated surfaces. Stainless steel, a high surface energy material, exhibits significant wetting and a very low water droplet contact angle (36 degrees, below left), causing moisture control problems. The Dursan low energy surface shows minimal wetting and a high contact angle, improving hydrophobicity and preventing adsorption, contamination and surface outgassing.

HPLC Metal Free Alternative to PEEK

SilcoTek® chemical vapor deposition technologies create a non-reactive surface that prevent interaction of test analytes with the stainless steel, glass and ceramic flow path surfaces. Our inert coating, Dursan®, improves peak quality and extends component life by preventing flow path corrosion.

SilcoTek® chemical vapor deposition technologies create a non-reactive surface that prevent interaction of test analytes with the stainless steel, glass and ceramic flow path surfaces. Our inert coating, Dursan®, improves peak quality and extends component life by preventing flow path corrosion.

The benefits of an inert flow path in HPLC include:

- Coat columns and frits for an inert surface like PEEK, but as robust as stainless steel. All the inertness and performance of PEEK without swelling, assuring consistent column performance.

- Improve peak shape, prevent lost peaks and improve test consistency.

- Improved performance with compounds like chelating agents, proteins, and biologics. Saving time and money getting the right results the first time, every time

Get all the information about the benefits of SilcoTek® coated analytical flow paths.

Get Our HPLC Application Note

Corrosion Resistance in Exhaust Abatement Systems

Exhaust systems and their associated abatement systems protect both the indoor and outdoor environment. System duct and components are frequently exposed to a mix of corrosives, high temperatures, and environmental conditions that can damage systems. Challenging conditions often result in costly shutdowns for maintenance.

Oxidation resistant, and corrosion resistant high purity coatings, like Silcolloy®, are often used in corrosive and high temperature exhaust applications. High durability coatings prevent corrosive attack and oxidation of the stainless steel and other alloys used in exhaust and emission control systems. Results can be surprising, with a service life extension of orders of magnitude over uncoated systems.

SilcoTek® coatings help to prevent common corrosion related problems including:

- Frequent component replacement

- Sample probe damage and failure

- Lost productivity due to excessive downtime

|

|

ASTM immersion testing proves SilcoTek® coated stainless steel enhances corrosion resistance by orders of magnitude, matching the performance of super alloys in many applications. Even after immersion in concentrated hydrochloric acid (below) the Dursan® coating and Silcolloy coated stainless steel coupons continue to perform with minimal corrosion, demonstrating performance comparable to super alloys.

/astm%20g31.png?t=1570811309696&width=454&name=astm%20g31.png) SilcoTek® coatings perform in a variety of corrosive environments including sulfuric acid and bleach as shown in the table below.

SilcoTek® coatings perform in a variety of corrosive environments including sulfuric acid and bleach as shown in the table below.

| Comparative Corrosion Summary |

|

|

| |

Stainless Steel Corrosion Rate (mpy) |

Dursan Coated Stainless Steel (mpy) |

| 6M Hydrochloric Acid, 24 hr exposure |

160 |

1 |

| 25% Sulfuric Acid, 24 hr exposure |

55 |

5 |

| 52 Week Salt Spray |

<0.01 |

<0.01 |

| Bleach |

1.7 |

0.1 |

Protein, Chelating Agents, Anti-Fungal Analysis, Blood Analysis

SilcoTek® coatings are used to prevent interaction of the test analyte with the flow path surface. Our inert coating, Dursan®, prevents adsorption, reactivity, and flow path corrosion. Applications include:

| |

- Analysis of chelating agents and other metal interactive compounds

- Phosphate analysis, prevent iron interaction

- Antifungal agent analysis

- Protein analysis and removal

- PEEK replacement in high durability applications

- Corrosion resistance applications

- Blood analysis

|

.png?width=600&name=Needle%20collage%20(002).png) |

|

Apply Dursan® to flow path surface to assure consistent results. Apply Dursan to:

- Needles & Syringes

- Nozzles

- Pump heads

- Metal fritted filters

- Stainless steel tubing

- Ampoules

- HPLC columns

- Valves and Fittings

- Clinical chemistry and immunoassay analyzers

- Mandrels, plungers, extrusion tips, dies

- Chemical vessels & containers

- Sensor probes

- Blood Centrifuges

- Cannulas

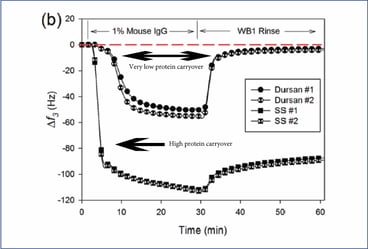

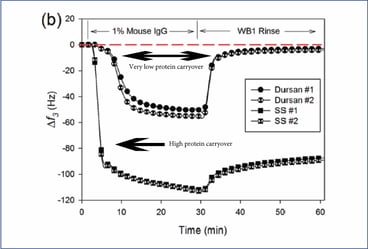

An inert, non-stick, nontoxic, high durability coating like Dursan® prevents protein binding, corrosion and biofouling in sampling flow paths. A study by Abbott Laboratories in Applied Surface Science demonstrate the bio-inertness performance and corrosion resistance of Dursan.

Comparative QCMD (quartz crystal microbalance with dissipation monitoring) characterization of the Dursan coating shows, when used with a non ionic surfactant rinse, a significant reduction in protein surface retention can be realized, preventing carryover and cross contamination. The graph below shows the Dursan surface (top line) returns to baseline weight after contact with the test protein analyte. The bottom line shows the stainless steel surface retaining the protein sample and not returning to baseline weight; indicating retention of protein. Read the entire paper here.

Food Flavor Fragrances

Inert Dursan coated stainless steel flow path components improve analytical resolution in food flavors and fragrances quality testing, while reducing biological interaction with the stainless steel surfaces that can cause contamination and foodborne illness. And because Dursan is corrosion resistant, the stainless steel flow path will last longer while reducing system maintenance.

Inert Dursan coated stainless steel flow path components improve analytical resolution in food flavors and fragrances quality testing, while reducing biological interaction with the stainless steel surfaces that can cause contamination and foodborne illness. And because Dursan is corrosion resistant, the stainless steel flow path will last longer while reducing system maintenance.

The benefits of SilcoTek coatings in Food, Flavors, and Fragrances applications include:

- Improve response and quality of fragrance analysis.

- Reduce protein binding and carryover of proteins

- Protect against cross-contamination, bacteria, and pathogens like Listeria.

- Increase system lifetime and productivity.

- Improve corrosion resistance, reduce metal impurities and contamination.

- Apply to legacy equipment for immediate benefit.

- Apply to hard to access parts and high risk contamination parts for added protection

Artificial Nose

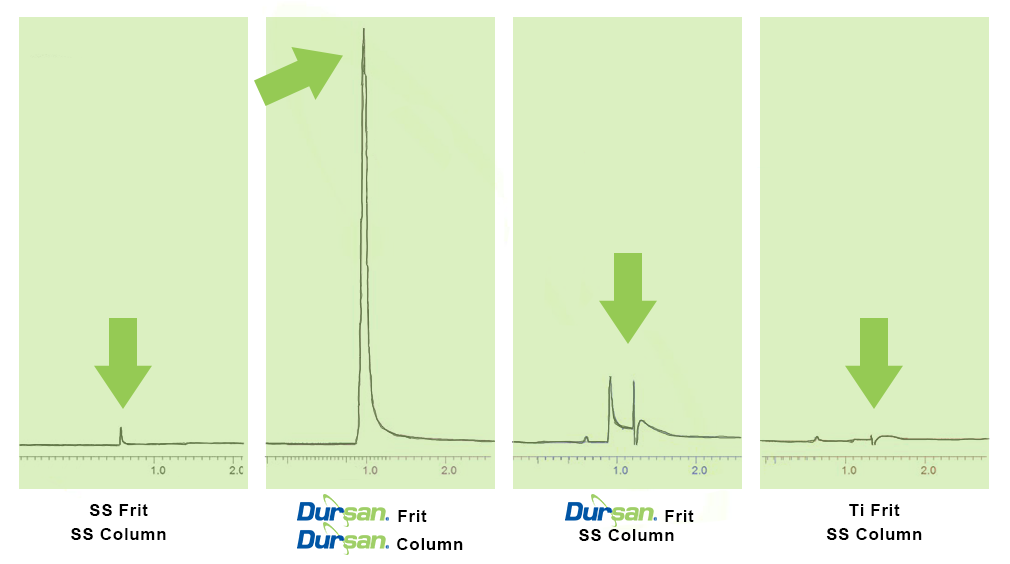

Precise detection of trace compounds in fragrances or odorants require surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and repeatably detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection the flow path surface must allow all the sample to reach the LC, GC or GC-MS detector.

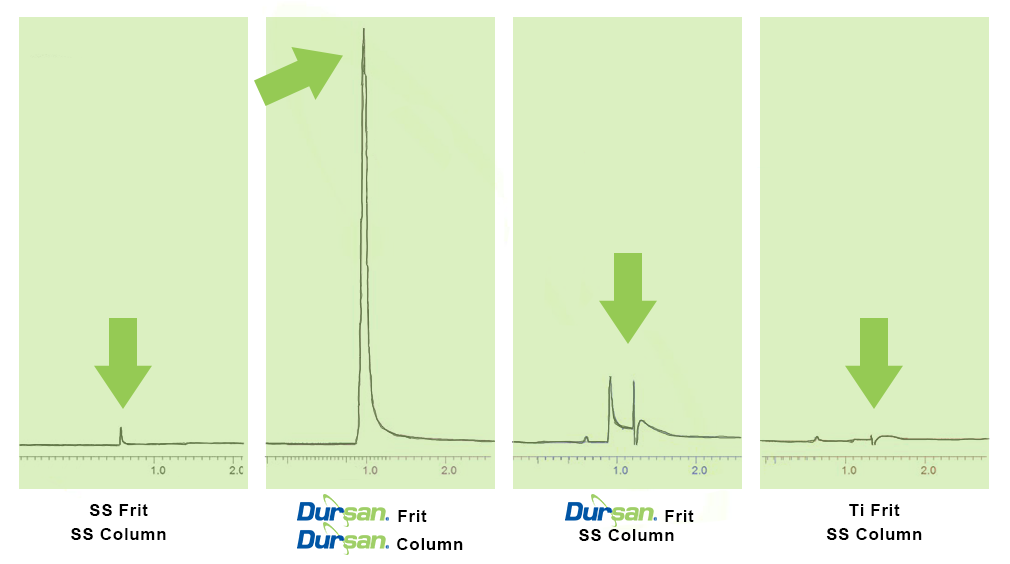

Comparing a prepared, known sample concentration in coated and uncoated HPLC systems. The first chromatogram shows the result when testing with a stainless steel frit and stainless steel column in the flow path. There is very little signal response, indicating flow path adsorption and loss of sample. This makes precise trace detection of target compounds difficult.

The next chromatogram shows results using a Dursan® coated frit and column. The peak is much larger and shows minimum tailing or distortion. This indicates that all the sample is reaching the column and detector without flow path adsorption. Making consistent detection of trace compounds for fragrance analysis or odor detection possible.

The other chromatograms at the right show how the same sample peak can be distorted when even part of the flow path is reactive.

Beer Clarity

Beer enthusiast, Jesse Bischof wondered if metal ion contamination, a known contributor to haze, could be controlled by coating the stainless steel fermenting vat with Dursan. We focused on our Dursan coating for this test because Dursan is NSF approved and has passed USP Class VI testing. Dursan is also known to reduce metal ion contamination in many environments.

To test this theory, R&D and Manufacturing teamed up to brew and compare the effect of Dursan coated surfaces on the clarity and taste of a pilsner style beer.

Comparative visual results monitored during and after the brewing process showed the Dursan coated fermenter produced significantly less haze. The photo below shows a comparison of the beer haze during the brewing process.

The odd numbered beakers are samples taken from the steel fermenter, and the even numbers are samples from the Dursan® coated fermenter. Samples were taken at 3 points during the brewing process.

- Beaker 1&2 show results after the mash (extracting the sugars from the barley to make wort)

- Beaker 3&4 show results from after the boil (adding hops and allowing the beer liquid to actually come together)

- Beaker 5&6 show the fermented beer before going into bottles for carbonation.

You can see how much clearer beaker 6 is over the uncoated sample in beaker 5.

Listeria Analysis and Cross Contamination Prevention

A collaborative research effort from the Department of Biomedical and Nutritional Sciences at the University of Massachusetts, Lowell and the Agricultural Research Service at the United States Department of Agriculture* showed the benefits of using Dursan on stainless steel as a means of reducing listeria biofilm formation.

The group investigated 304 stainless steel with a variety of surface textures and FDA compliant coatings. Of all the treatments, the Dursan® process applied to a native 304 surface showed the best results. Dursan also showed promise on a textured surface, eliminating the need for the change in topography.

The biofilm formation was quantified in two different ways: CV staining and plate counts. CV staining shows the total mass of biological substance that was on the sample surface while the plate counts show how much of that substance is viable cells that can make a person sick.

The CV staining results show that only 3 coatings provide statistically lower biomass accumulation: Dursan, Ni-P-PTFE, and CrN.

.png?width=489&name=Listeria%20CV%20Staining%20(003).png) CV staining results of all 18 samples. The symbols over the coated samples symbolize statistical difference (P-values) for each result. **: P<0.001 or significantly different from the uncoated control, *: 0.001<P<0.05 or statistically different from the control, and∇: P>0.05 or not statistically different from the control.

CV staining results of all 18 samples. The symbols over the coated samples symbolize statistical difference (P-values) for each result. **: P<0.001 or significantly different from the uncoated control, *: 0.001<P<0.05 or statistically different from the control, and∇: P>0.05 or not statistically different from the control.

The results of the viable cell counts from each surface showed that, regardless of the surface topography, Dursan is the only coating that is able to decrease active cells from the surface. Results showed up to a 4 order of magnitude reduction in viable cell count.

.png?width=515&name=Listeria%20Active%20Cells%20(003).png)

Measurement of active listeria cells on the surface of various coupons. The indicators over the bars are the same as they were for Figure 2 where ** shows a significant statistical difference from the control, * shows statistical difference, and ∇ shows essentially no statistical difference.

* "Listeria monocytogenes biofilm formation as affected by stainless steel surface topography and coating composition"; TingtingGua; ApisakMeesrisoma; YaguangLuob; Quynh N.Dinha; SophiaLina; ManyunYang; ArnavSharma; RuoguTang; JindeZhang; ZhenJia; Patricia D.Millner; Arne J.Pearlstein; BoceZhang: Food Control, Volume 130, December 2021, 108275

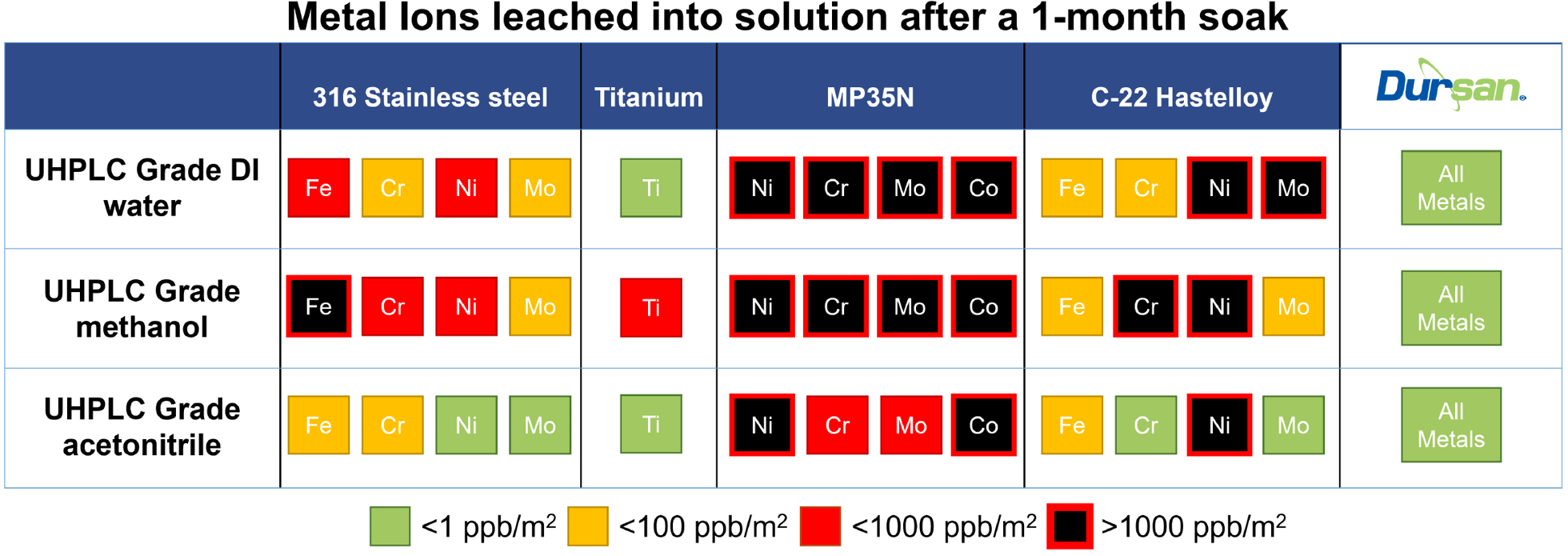

Metal Contamination

Chemical exposure to solutions, such as, organic solvents, deionized water, acids or bleach, can cause a significant amount of metal ions to dissolve into the liquid, causing product contamination, system corrosion, and test problems in analytical and high purity processes.

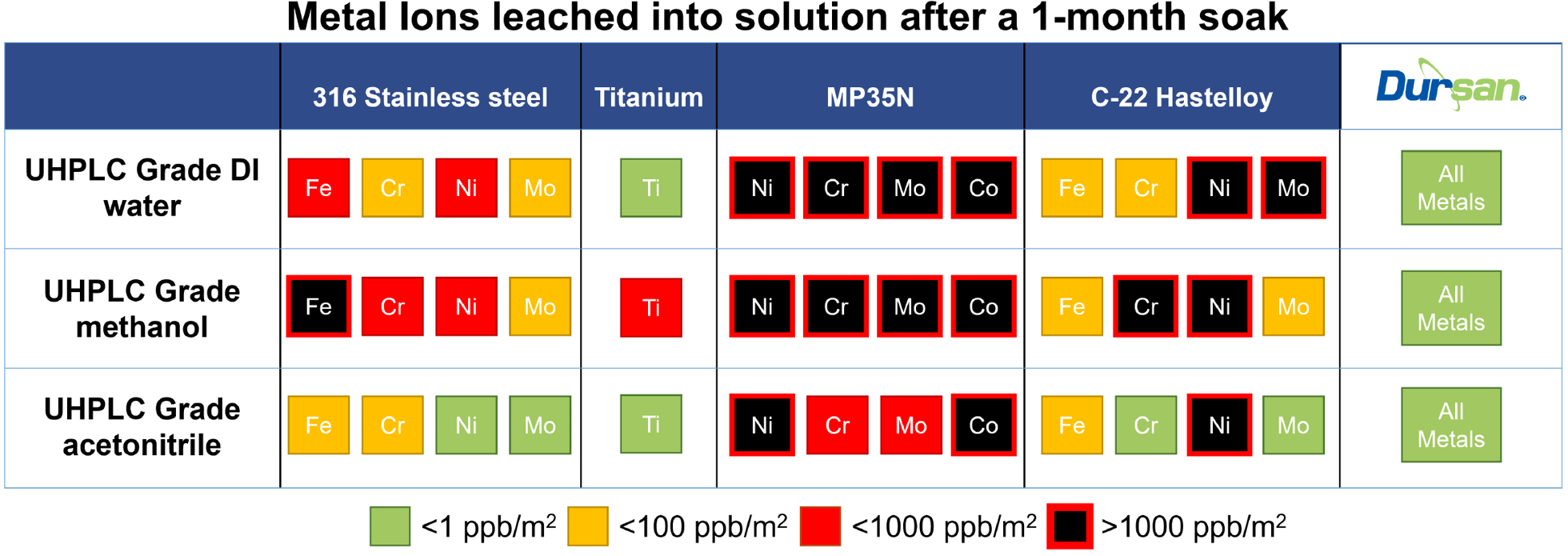

SilcoTek® offers CVD coating solutions to make your process, analytical, and sampling systems perform better. Our chemically inert coatings improve test accuracy and reliability by preventing metal contamination from metal ion leaching caused by chemical reactions between the product and flow path surface. The summary below demonstrates how metal ions can be readily leached into flow path solutions and how coated surfaces (right column, green) prevent contamination under all conditions tested.

SilcoTek's CVD silicon coating process bonds inert, non-reactive coatings like Dursan®, Silcolloy®, and SilcoNert® to the surface. The chemically inert coatings prevent interaction of the sample with the reactive flow path surface. Interested in learning more about our coatings and how they perform in your application? Get a Free Coating Consultation or follow us on LinkedIn.

First, a

First, a Another use for Real-time VOC analysis is in exercise analysis. A publication from 2021 attempted to utilize VOC analysis from exhaled breath to potentially replace blood testing to analyze shifts in metabolites in the body. During exercise, these VOC and metabolite shifts are largely due to a change in fatty acid oxidation, glycolysis, and the Krebs cycle. There are several unknowns regarding the efficiencies of exercise plans, the individual genetic makeup of a person that may lead to non-optimal exercise (or potentially harmful exercise for an individual), as well as how one’s diet may impact exercise efficiencies. This publication was successful in analyzing VOCs from exhaled breath and matching them quite well with what is typically done via blood draws from athletes after moderate exercise. The advantage of real-time and non-invasive analysis techniques may lead to useful analysis in monitoring disease, medication response, and changes in metabolic and physiological functions.

Another use for Real-time VOC analysis is in exercise analysis. A publication from 2021 attempted to utilize VOC analysis from exhaled breath to potentially replace blood testing to analyze shifts in metabolites in the body. During exercise, these VOC and metabolite shifts are largely due to a change in fatty acid oxidation, glycolysis, and the Krebs cycle. There are several unknowns regarding the efficiencies of exercise plans, the individual genetic makeup of a person that may lead to non-optimal exercise (or potentially harmful exercise for an individual), as well as how one’s diet may impact exercise efficiencies. This publication was successful in analyzing VOCs from exhaled breath and matching them quite well with what is typically done via blood draws from athletes after moderate exercise. The advantage of real-time and non-invasive analysis techniques may lead to useful analysis in monitoring disease, medication response, and changes in metabolic and physiological functions.

SilcoTek® chemical vapor deposition technologies create a non-reactive surface that prevent interaction of test analytes with the stainless steel, glass and ceramic flow path surfaces. Our inert coating, Dursan®, improves peak quality and extends component life by preventing flow path corrosion.

SilcoTek® chemical vapor deposition technologies create a non-reactive surface that prevent interaction of test analytes with the stainless steel, glass and ceramic flow path surfaces. Our inert coating, Dursan®, improves peak quality and extends component life by preventing flow path corrosion.

/astm%20g31.png?t=1570811309696&width=454&name=astm%20g31.png)

.png?width=600&name=Needle%20collage%20(002).png)

Inert Dursan coated stainless steel flow path components improve analytical resolution in food flavors and fragrances quality testing, while reducing biological interaction with the stainless steel surfaces that can cause contamination and foodborne illness. And because Dursan is corrosion resistant, the stainless steel flow path will last longer while reducing system maintenance.

Inert Dursan coated stainless steel flow path components improve analytical resolution in food flavors and fragrances quality testing, while reducing biological interaction with the stainless steel surfaces that can cause contamination and foodborne illness. And because Dursan is corrosion resistant, the stainless steel flow path will last longer while reducing system maintenance.

.png?width=489&name=Listeria%20CV%20Staining%20(003).png)

.png?width=515&name=Listeria%20Active%20Cells%20(003).png)