We discuss coatings for mass spectrometry systems and why they're used. Read on to learn how coatings enhance the performance of MS systems.

Coatings for Mass Spectrometry (MS) Systems

SilcoTek® coatings have been used to enhance the performance of mass spectrometry systems for nearly 30 years. From our earliest coating, Silcosteel, to more contemporary coatings like SilcoNert 2000, SilcoGuard, and Dursan; SilcoTek has been an integral part of MS systems. But why are so many different coatings used? What's the benefit of using so many different coatings? And where are the coatings used? We discuss applications and benefits of CVD coatings for GC-MS, LC-MS and MS-MS systems. We'll also reference a few real world examples demonstrating the capabilities of SilcoTek coatings.

|

In this blog post you will learn:

- How various coatings are used in MS systems.

- How MS systems benefit from the use of high durability, inert coatings.

- Learn about some interesting coating applications in MS systems.

|

About Mass Spectrometry

Very generally speaking, in a basic MS system a sample is bombarded with an electron beam in order to ionize (break up sample fragments) into varying degrees of positive charge. The ion fragment masses are then separated by charge, detected by an electron multiplier, and displayed as a spectra of the intensity based on a mass to charge ratio. The results are correlated to known masses. You can read about mass spectroscopy in more detail here.

So a gas chromatography MS system or liquid chromatography MS system will take a sample, complete the separation through a column and then send the sample through the mass spectrometer to further speciate and identify the contents of the sample on an atomic or molecular scale. All this sample transport, separation and analysis can be complex and will involve transporting and exposing the sample to a range of potentially adsorptive, or contaminating surfaces. That's where our coatings come into play.

How Coatings are Used in MS Systems and Their Benefits*

How Coatings are Used in MS Systems and Their Benefits*

Depending on the test conditions, sample, and desired result, various coatings may be used throughout the MS sample flow path. 30 years ago when our coatings were in their infancy, a manufacturer needed a coating that prevented stainless steel surface adsorption on electrode surfaces (they basically didn't want ions attaching to the surface of the electrode). They also needed a coating that did not disrupt the electrical charge characteristics of the system. We found that our first coating, Silcosteel® (now called SilcoNert® 1000) performed well in the application. That was the first use of silicon CVD coatings in MS systems.

From there, continued and ever changing detection requirements resulted in the development of SilcoNert® 2000 (known as Sulfinert® and also Siltek® in analytical circles). SilcoNert 2000 further improved the surface inertness and non-reactivity of stainless steel surfaces. Analysts caught on and started coating the flow paths of GC-MS systems with SilcoNert 2000. This enabled a higher degree of trace detection by preventing adsorption of sample compounds by stainless steel flow path components and greatly improving inertness response of the system.

/Inertness%20Response.png?width=464&name=Inertness%20Response.png)

So now coatings are found in the sample collection, sample transport, and internals of GC-MS systems.

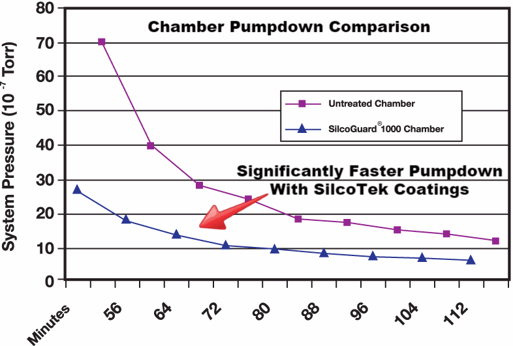

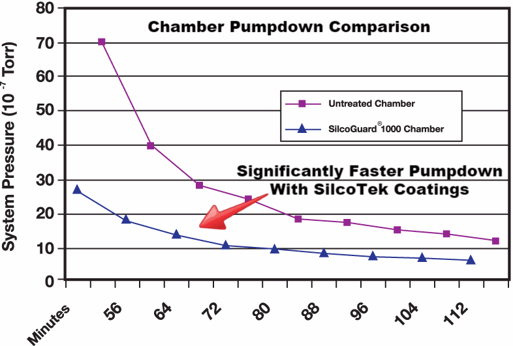

We continued to refine and develop new coatings in subsequent years. The new coatings were designed to fill needs in analytical and industrial applications. Silcolloy® was developed to improve corrosion resistance of stainless steel, SilcoKlean® was developed to prevent surface fouling, and SilcoGuard® was developed to reduce outgassing of stainless steel in ultra high vacuum systems. And that's where the third coating application in MS systems came to be. Stainless steel MS system chambers and components can outgas which can contaminate the system or at minimum result in longer vacuum pump-down cycles. SilcoGuard, a hydrogenated amorphous silicon (a-Si:H) coating, improved vacuum pump down efficiency in MS systems and, because the coating is mostly inert silicon, the potential for system contamination was reduced.

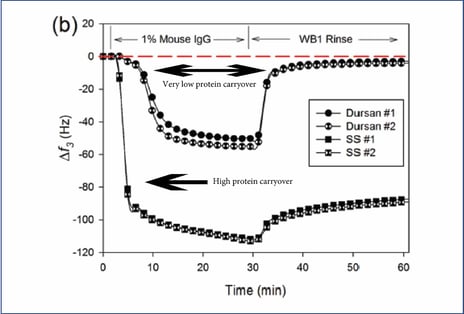

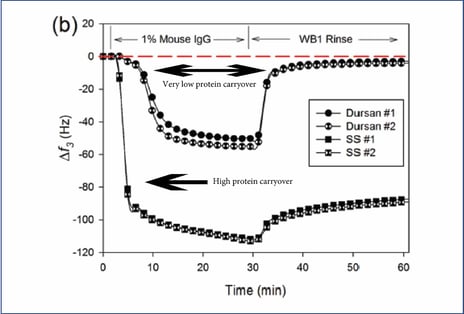

After a few years later, Dursan® was developed as a higher durability non-reactive inert coating for use in sliding or minor friction applications. Later testing in high performance liquid chromatography (HPLC) applications found that Dursan was also improved bio-inertness in some applications. Dursan was found to reduce protein carryover and contamination by reducing protein binding action to the flow path surface.

This discovery resulted in Dursan being applied to HPLC flow path surfaces. Further testing resulted in many benefits for HPLC-MS applications including:

This discovery resulted in Dursan being applied to HPLC flow path surfaces. Further testing resulted in many benefits for HPLC-MS applications including:

- Analysis of chelating agents and other metal interactive compounds

- Phosphate analysis, prevent iron interaction

- Antifungal agent analysis

- Protein analysis

- PEEK replacement in high durability applications

- Corrosive applications

- Metal ion contamination prevention

Where are CVD Coatings Used in MS Systems:

Over the years CVD coatings have become a mainstay in analytical and specifically mass spectrometry systems. Today our CVD coatings are used in many parts of the flow path. Some examples include:

|

Sampling and Sample Transfer

- Pumps

- Tubing

- Valves

- Fittings

- Cylinders and canisters

- Ampoules

|

Calibration

- Valves

- Regulators

- Fittings

- Filters and filter bodies

|

|

Coating GC and GC-MS Flow Paths

- Injection ports

- Liners

- Tubing

- Valves and fittings

- Analytical columns

- MS chambers

- Electrodes

|

Coating LC and LC-MS Flow Paths

- Pumps

- Tubing

- Columns

- MS chambers

- Electrodes

|

To make using our coatings easier, you can buy coated products directly from the manufacturer and save time! Just click the button below to go to our products page.

Coating Applications for MS Systems

There are many papers that highlight our coatings in MS systems. Some applications take our coatings to space, others are more worldly, but all demonstrate how our coatings help to improve the performance of mass spectrometry systems. Here are a few examples:

There are many papers that highlight our coatings in MS systems. Some applications take our coatings to space, others are more worldly, but all demonstrate how our coatings help to improve the performance of mass spectrometry systems. Here are a few examples:

SilcoTek® continues to develop new coatings for MS and other analytical applications. We have a new coating on the horizon that will continue to advance analytical science and improve customer products worldwide. Stay in touch with the latest in coating development to learn more about exciting new coatings. Subscribe to our blog, or follow us on LinkedIn.

*Image courtesy of the Czech Museum of Mass Spectrometry.

How Coatings are Used in MS Systems and Their Benefits*

How Coatings are Used in MS Systems and Their Benefits*

/Inertness%20Response.png?width=464&name=Inertness%20Response.png)

This discovery resulted in

This discovery resulted in

There are many papers that highlight our coatings in MS systems. Some applications take our coatings to space, others are more worldly, but all demonstrate how our coatings help to improve the performance of mass spectrometry systems. Here are a few examples:

There are many papers that highlight our coatings in MS systems. Some applications take our coatings to space, others are more worldly, but all demonstrate how our coatings help to improve the performance of mass spectrometry systems. Here are a few examples: