Getting the performance results you want from process or analytical systems requires good design as well as thought toward maintaining the system throughout its life.

Getting the Most Out of Your Analytical or Process System

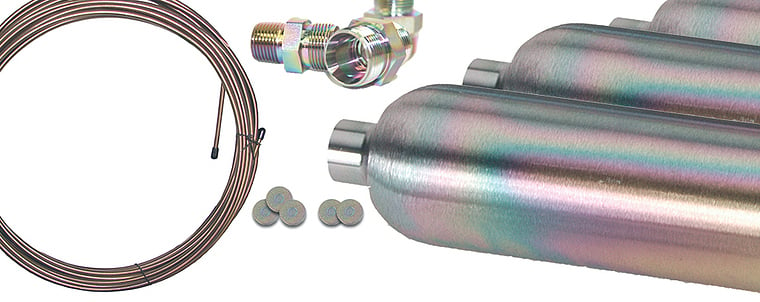

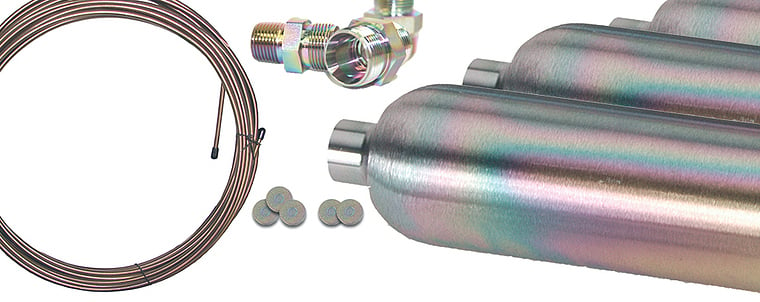

At SilcoTek we coat thousands of process and analytical flow path components, like, tubing, fittings, valves, sample cylinders and other flow path components, a year with our inert CVD barrier coatings. We know that for the customer to get the most out of their process or products, they not only need a high purity corrosion resistant barrier coating, they need reliability.

Customers need to understand that proper component selection, careful assembly, and periodic maintenance of silicon coated flow path components can mean the difference between getting reliable results efficiently and system failures. Nobody wants a system failure and they don't want yield or product failures. That's why taking a few simple steps before and after product use make all the difference.

|

In this blog post you will learn.

- Get tips on design, selecting and using coated flow path components

- Things to look for when inspecting a analytical flow path components to assure coating purity and durability

- Get tips on flow path component care and maintenance tips when living with inert silicon coatings

|

Selecting the Right Components

When building a process sampling system, analytical flow path, or any product system that utilizes SilcoTek coatings; be sure to use flow path components that assure proper long term operation. Components should be properly sized for the application, our coatings don't significantly impact component dimensions or volumetric calculations but they should be able to be disassembled in order to be properly coated and inspected.

Internal O-rings, plastic components, or other parts not rated for our process temperatures cannot be coated. You'll also need to select the right coating for your application. We have an easy online tool that can help you choose the right coating that best fits your applications. Click on the box below to go to our Coating Selection Guide.

Sample Cylinders

- Do you need a constant pressure or constant volume sample cylinder? If you're concerned about the phase change of the sample liquid, you may want to consider using a constant pressure sample cylinder. They're more expensive, but you're assured of measuring the process fluid under the right conditions.

- Do you need a dip tube? A dip (or outage tube) are used to preserve some vapor space above liquefied gases. The dip tube allows only partial filling of the sample cylinder so the remaining vapor space can take up expansion of the liquid when the sample cylinder is exposed to higher temperatures. That helps to maintain cylinder pressure and avoid over pressurizing the sample cylinder. Here's a good explanation on how to calculate the desired vapor space in the sample cylinder from Tom Bloom at Restek® Corp.

- Dip tube length = % outage x cylinder length, i.e. a 50% outage on a 10in sample cylinder (.5x10) equals a dip tube length of 5in. (note this is an approximate calculation, consult the sample cylinder manufacturer for recommended length for their specific sample cylinder).

- Select for the right pressure and environment. Select valve and sample cylinders that are pressure rated to exceed the expected pressure of the sample stream. Do not exceed the rated pressure of the canister or valve. Note that most canisters are rated at an ambient temperature of around 100°c. If the sample environment exceeds the rated temperature contact the manufacturer to be sure the system pressure capabilities will not be exceeded.

Need help finding the right coated sample cylinder or valve? You can find manufacturers that offer inert coated sample cylinders, valves, fittings, filters and regulators on our Buy Coated Products Page.

Selecting the Right Valve

Selecting the Right Valve

- Do you need a ball valve or needle valve? Do you need fine control of the product flow? Go with the needle valve. Does the valve have a burst disk to prevent sample cylinder failure. How durable is the valve? Will the valve be "cranked closed" in the field with a wrench? That will surely ruin the seat, so consider using a high durability sample cylinder valve with design features that prevent over tightening.

- There are many high quality valve manufacturers out there. It's a good idea to look within your field of use to find what combination of cylinders and valves work for your application. Consult others in your field and trade papers to get recommendations.

- Do you need a filter? To avoid particulate contamination it's a good idea to install a sintered metal frit filter upstream of the canister.

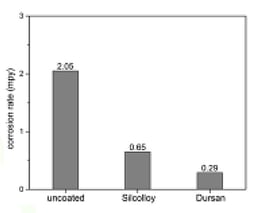

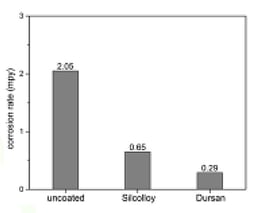

- Be sure to coat the filter and canister with Silcolloy®, Dursox® or Dursan® to improve corrosion resistance. HBr corrosion rate is significantly reduced after applying a silicon barrier coating to the stainless steel surface. 24 hour immersion studies show Silcolloy and Dursan reduce corrosion rates by up to an order of magnitude. After immersion, the Silcolloy and Dursan test coupons remain corrosion free.

|

HBr Corrosion Rate HBr Corrosion Rate

|

Coupons after HBr corrosion testing

|

Tubing

When installing SilcoTek coated tubing you should follow the general design criterial outlined by the tubing manufacturer. Our coating will not change the pressure rating or flow characteristics of the tubing. Calculate the flow rate and overall product volume the systems needs to convey. Then match tubing specifications to desired performance. Most tube suppliers offer detailed product data, using an example from Handy Tube Corporation, you can see their data sheets offer extensive information about tube sizing and capabilities.

Assembling Flow Path Components

Inspect canisters, fittings, valve, or regulators or other threaded components for damage, especially on the threads. Check for burrs, gouges or nicks, crossed thread damage, galling damage and damage to the valve seat. If you're using a relief valve, be sure there is no sign of damage to the relief valve or burst disk. Repair any damage and thoroughly clean threads before assembly. Inspect the inside shoulder of the sample cylinder or canister for corrosion and particulate matter.

Thread Inspection and Galling

Galling can occur when two parts of similar material are connected under compression and the heat generated "cold welds" the parts together. Galling can occur when threading valves into stainless steel sample cylinders. Also galling can occur when two SilcoTek® treated threads, compression fittings or NPT fittings are assembled. Be sure to apply PTFE tape to valve threads when assembling sample cylinders.

If both mating parts must be coated, then SilcoTek recommends using anti Seize compounds made from Silver, Moly or Nickel: For sample cylinder applications refer to the instructions pertaining to the use of Teflon tape on the valve NPT prior to installation. Want to learn more about thread galling? Here's a thorough article on galling from Machine Design.

Cleaning SilcoTek Coated Surfaces

For processes that require optimal cleanliness and purity, clean components before assembly. Components should be cleaned to oxygen service specifications or better, if using for high purity applications. Be sure the solvent used for cleaning will not leave a residue. Solvent residue can be as big a contamination source as the material being cleaned. Here are some tips for cleaning SilcoTek® coated products:

- When cleaning a coated part, rinse with a high purity solvent that will dissolve surface contaminants.

- Use a nonpolar solvent, like pentane or hexane, to remove hydrocarbon contaminants; or use a more polar solvent, like acetone, to remove more active contaminants.

- Avoid using cleaners containing abrasives. Abrasives can scratch the coating surface.

- Mild sonication may assist in contaminant removal. Do not sonicate the surface for more than 1 minute.

- Solids can be removed with a soft nylon bristle brush, using light pressure.

- Do not use basic solutions or soaps with a pH greater than 8.0.

- Do not steam clean SilcoTek coated surfaces; this can damage the layer.

- For high purity applications, SilcoTek recommends the cleaned surface be tested to confirm trace cleaning solvents are completely removed and surface activity is not compromised.

- Do not steam clean surfaces. Process steam can damage the coating surface and introduce reactive particulates into the sample cylinder.

- After cleaning apply PTFE tape to valve threads. To assure a leak tight seal, wrap the threads 3 times with a high quality PTFE tape. Leave the first threads exposed to assure positive thread engagement.

- Engage threads manually (2-3 turns by hand). Threads should engage easily and smoothly. If threads do not engage smoothly, check again for damage or burrs. Never force threads.

- Tighten valves using a torque wrench. Torque to manufacturers specifications (usually a maximum of 8 to 10 ft-lbs). Threads should engage another 2-3 turns. Clamp cylinder assembly prior to torqueing valves to facilitate the assembly process. Protect the cylinder from damage, scratches or gouging. Gouging the cylinder may compromise the pressure rating of the sample cylinder.

Keeping your coated products running at peak performance

Develop an inspection plan and keep an inspection calendar to be sure sample cylinders and valves, regulators or other critical components are periodically inspected. Inspection tips include:

- Check for changes in surface color. If the coating color changes, that may be a sign of coating loss.

- Inspect for particulates

- Check for damage to cylinder, valve or burst disk.

- Inspect for corrosion

- Inspect threads for damage and fouling

- Check for signs of leaks

For Silcolloy® and Dursan® coated cylinders, layer appearance and surface finish can vary from lot to lot. Small variations in surface thickness (measured in angstroms) can impact layer appearance. The surface finish should be bright and free of defects, but original surface condition can have a major impact on final surface quality.

Treatment Layer Troubleshooting

Under normal use, your treated items should deliver outstanding performance for years to come. However; effective lifetime is dependent on the severity of the environment. Factors that can impede performance are:

- Contamination: Failure to properly clean the surface can allow increased surface activity. If performance changes, thoroughly clean the surface and inspect the layer for damage.

- Erosion: Contact with abrasives can accelerate surface wear.

- Bases: Contact with a base (pH 8 or higher) can accelerate deterioration of the layer (Silco-coatings only).

- Surface finish: Surface finish and color should stay consistent throughout the life of the product.

- Changes in the finish or color may indicate a partial loss of the layer. To prevent further loss, ensure no exposure to bases or abrasives.

- Abuse. Damage to the sample cylinder or valve may require replacement.

Get more benefits! Go to our Sample Transfer Solutions page to learn how to improve your process through better sampling. Or get sample transport tips from industry leaders, join us on LinkedIn.

Selecting the Right Valve

Selecting the Right Valve HBr Corrosion Rate

HBr Corrosion Rate