For researchers finding a coating that has minimal light transmission can be critical to the success of their project. Let's discuss light and how super thin silicon CVD coatings enhance performance.

How is Light Transmitted Through Silicon Coatings

|

In this blog post you will learn:

- How thin silicon coatings change light transmission.

- How silicon CVD coating thickness impacts color.

- Benefits of low light transmission CVD silicon coatings.

|

Background

Light is basically electromagnetic waves that are all around us. Some can be seen, visible light with wavelength ranging from 400-700 nm, some cannot such as infrared's longer wavelength and ultraviolet with shorter wavelengths.

Transmission is basically that "light" moving through something. Reflection is what light that is bounced back from the object the light hits. Absorption accounts for what light is not bounced back or taken up by the body. Light can also be spread into interference patterns which makes those really cool prisms so fun to use.

Coating Color and Light Transmission

Most coatings, like paint, absorb some visible light waves and reflect back a portion of that light in the form of color. That's why the color red looks red (red pigment that reflect red color spectrum) and not white (most light reflected back) or black (no light reflected back).

SilcoTek coatings do not contain pigments (like paint). Pigments get their color because they absorb most of the white light and reflect back only the color you see. In fact our coatings are made primarily of silicon which in natural form looks like a gray shiny rock. So how does a gray rock become a shiny rainbow? Or adsorb minimal color? It all has to do with super thin coatings and light refraction and absorption and interference. Want to learn more about CVD coating material properties? Go to our Coating Material Property and Specifications Page.

The CVD coating process and how it makes color.

We bond silicon to metals, glass, or ceramics through a process called chemical vapor deposition (CVD). This process allows us to build a silicon layer on a surface one Angstrom (0.1 nanometer) at a time. A super thin layer of silicon is pretty clear, in fact you can see through a thin silicon layer. As the silicon thickness increases on say a stainless steel surface, light which travels through the silicon is bent. The light then reflects off the stainless surface and is bent again. All this light bending causes some wavelengths of light to cancel out each other while other wavelengths are reinforced. The canceled (or interference) wavelengths aren't seen by your eye while the reinforced wavelengths hit your cones and are seen as color. Changing the color of a thin silicon surface is easy, a few nanometer change in silicon thickness can have a big impact on the colors you see.

The best analogy of this effect that I can relate to is oil on water. I'm sure you've noticed that after a rain storm a colorful rainbow oil slick can be found flowing from under that 1966 Mustang that's been parked in your driveway and waiting to be restored for the past 8 years. I know you'll get to it.... Anyway, oil is not colorful, it's either honey colored when new or black when draining from your oil pan. That black oil is becoming a colorful rainbow because of refraction. Light reflects off the top of the oil surface and also travels through the thin oil and is reflected back from the water surface below the oil. Depending on the thickness of the oil, light rays will either be reinforced or interfered with by the oil refraction. When the rays of light reach your eye, the destructive interference wavelengths cancel each other out. The oil thickness variation dictates what colors you see and what color wavelengths get canceled out. So a slight variation in thickness can have a big impact on the color you see and on the transmission of the light spectrum.

The best analogy of this effect that I can relate to is oil on water. I'm sure you've noticed that after a rain storm a colorful rainbow oil slick can be found flowing from under that 1966 Mustang that's been parked in your driveway and waiting to be restored for the past 8 years. I know you'll get to it.... Anyway, oil is not colorful, it's either honey colored when new or black when draining from your oil pan. That black oil is becoming a colorful rainbow because of refraction. Light reflects off the top of the oil surface and also travels through the thin oil and is reflected back from the water surface below the oil. Depending on the thickness of the oil, light rays will either be reinforced or interfered with by the oil refraction. When the rays of light reach your eye, the destructive interference wavelengths cancel each other out. The oil thickness variation dictates what colors you see and what color wavelengths get canceled out. So a slight variation in thickness can have a big impact on the color you see and on the transmission of the light spectrum.

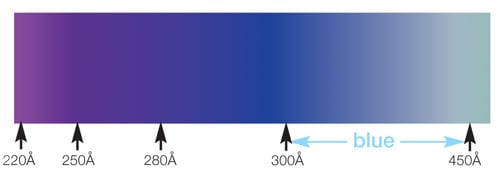

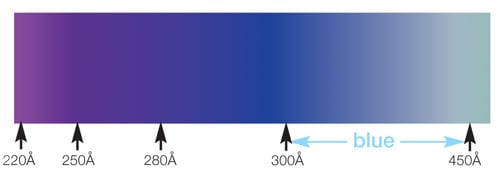

The same holds true with silicon. Small variations in thickness can make a big difference in the color of the coating. So the different colors observed on Silco'd treated parts indicate different layer thicknesses. A blue color corresponds to a 300 to 450 Angstrom layer while a rainbow color indicates a coating of at least 1200 Angstroms (120 nanometers).

Colors associated with layer thickness are:

Deposition thickness of Silcolloy® and SilcoGuard® processes max out at 1µm (1000nm) and have a rainbow to silver/metallic gray appearance. The photos below show colors created by SilcoNert®, a 500nm** coating (left) and Silcolloy®, an 800nm** coating (right). So as you can see, a few nanometers change in thickness will result in a dramatic change in the color of the part.

Light Transmission of CVD Silicon Coatings

At times research teams require an inert surface that absorbs minimal light usually at a particular target wavelength. For longer wavelengths, our silicon coatings (basically hydrogenated amorphous silicon) would have minimal effect on light transmission.

For example, when comparing to a specific wavelength (say 1550 nm), the thickest hydrogenated amorphous silicon coating we have (Silcolloy) is only 800 nm thick. That would translate to ~0.00104 dB, so 99.98% transparent.

SilcoTek has not measured optical transparency directly; however, a graduate school colleague at The Pennsylvania State University did his graduate work on depositing materials very similar to our SilcoNert coating (hydrogenated amorphous silicon) for optical waveguides. The telecommunication wavelength is 1550 nm, so this was the wavelength of interest for their measurements. In his dissertation, they measured optical losses anywhere from 0.8 dB/cm up to 13 dB/cm. Since our coating is at most 500 nm for SilcoNert, that would translate to 0.00004-0.00065 dB. For reference, 0.001 dB is 99.98% transmission, the lower the value the higher the transmission.

Due to the very thin nature of SilcoNert 2000 and its optical transparency at that wavelength, it will not absorb an appreciable amount of light if in the 90-95% transmission range.

Have a question about our coating properties? Our senior coating scientists can help you select the best coating for your application, and can provide data or recommend the best ways to evaluate a coating.

Where to Get More CVD Coating Information

OK, SilcoTek CVD coatings may meet my optical transparency requirements but what are the performance benefits? Our coatings offer improved corrosion resistance, superior inertness and non reactivity, and fouling resistance. Our coatings are used in many industries and applications in analytical, medical diagnostics, oil and gas, semiconductor and of course research and specialty applications. Our coatings help achieve ppq performance in the lab and processes while minimizing light transmission effects.

Will a SilcoTek® coating work in my application? That depends on the light wavelength and coating thickness and overall desired performance requirement and benefit. If you're interested in finding an inert, corrosion resistant coating with higher transmission rates, contact our Technical Service Team, or go to our Frequently Asked Questions page. We'll be happy to discuss your application and do our best to match a coating that offers optimal performance for your application.

The best analogy of this effect that I can relate to is oil on water. I'm sure you've noticed that after a rain storm a colorful rainbow oil slick can be found flowing from under that 1966 Mustang that's been parked in your driveway and waiting to be restored for the past 8 years. I know you'll get to it.... Anyway, oil is not colorful, it's either honey colored when new or black when draining from your oil pan. That black oil is becoming a colorful rainbow because of refraction. Light reflects off the top of the oil surface and also travels through the thin oil and is reflected back from the water surface below the oil. Depending on the thickness of the oil, light rays will either be reinforced or interfered with by the oil refraction. When the rays of light reach your eye, the destructive interference wavelengths cancel each other out. The oil thickness variation dictates what colors you see and what color wavelengths get canceled out. So a slight variation in thickness can have a big impact on the color you see and on the transmission of the light spectrum.

The best analogy of this effect that I can relate to is oil on water. I'm sure you've noticed that after a rain storm a colorful rainbow oil slick can be found flowing from under that 1966 Mustang that's been parked in your driveway and waiting to be restored for the past 8 years. I know you'll get to it.... Anyway, oil is not colorful, it's either honey colored when new or black when draining from your oil pan. That black oil is becoming a colorful rainbow because of refraction. Light reflects off the top of the oil surface and also travels through the thin oil and is reflected back from the water surface below the oil. Depending on the thickness of the oil, light rays will either be reinforced or interfered with by the oil refraction. When the rays of light reach your eye, the destructive interference wavelengths cancel each other out. The oil thickness variation dictates what colors you see and what color wavelengths get canceled out. So a slight variation in thickness can have a big impact on the color you see and on the transmission of the light spectrum.